Technology has advanced in ways that improve convenience and flexibility in everyday life. But, modern technology has also been at the forefront of solving major logistics and operational challenges for businesses and enterprises. Below, we’ll go into detail about how technology has influenced and advanced warehouses, and how security and operations can be improved by deploying these new solutions.

Table of contents

- Warehouse Security and Access Control

- Smart Packaging

- Warehouse Automation

- AI-Powered Machine Vision

Suggested Posts:

- Smart Intercom System for Apartments

- Challenges of Modern Apartment Delivery Management

- Best Package Management Solutions for Multifamily Buildings

Warehouse Security and Access Control

Warehouses need the highest level of security and access due to the millions of dollars of inventory that pass through them every day. Currently, the complex logistics involved with managing an industrial warehouse, storage facility, or manufacturing plant are leaving gaps in security protocol. Luckily, new access control technology is effectively managing loss prevention for warehouses.

Cargo Theft in the US

According to the FBI, loss due to cargo theft per year in the US is estimated at $100 million. However, cargo theft is a vastly under-reported crime and not all states even report their numbers to the FBI. So, it’s generally agreed upon that cargo theft is closer to a $15 to $30 billion-dollar problem each year in the United States.

Cargo theft includes loss during transit, but mostly refers to theft that occurs in or at the warehouse. For example, during Labor Day weekend 2018, $5.7 million worth of cell phones were stolen from a warehouse in Delaware. That same weekend, $1.5 million worth of equipment was stolen from a warehouse in California.

With the growth of ecommerce and reliance on internet-based enterprises for basic necessities, warehouses are busier and more occupied than ever. Which is why their security can no longer be taken for granted.

Modern Warehouse Access Control

Warehouses have dozens of access points dispersed throughout the entire facility. They also have teams of employees and vendors coming on and off site daily. Managing warehouse access with onsite legacy systems and key card distribution is no longer the most secure or efficient way to operate security. Improving warehouse security means upgrading to:

- Cloud-based access management, and

- Mobile or face recognition access credentials

1. Cloud-Based Access Management

Cloud-based access control allows warehouse administrators to manage security from anywhere. Instead of managing access points and credentials on site, it can all be done remotely from the cloud. This eases the operational and administrative burden by centralizing the entire warehouse security management. Cloud-based access management also allows administrators to view access events in real time. This increases overall security visibility, which is particularly beneficial for warehouses who oftentimes have night shift employees and security.

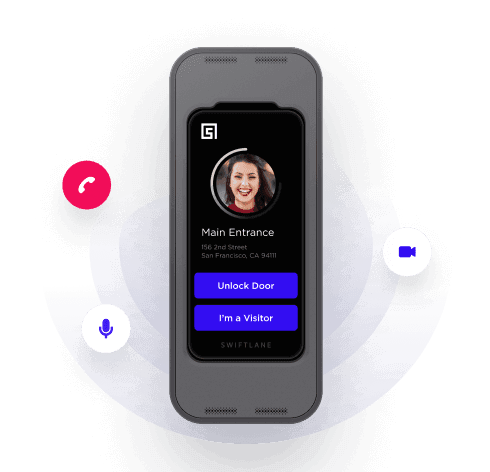

2. Mobile or Face Recognition Access Credentials

Access control as an industry is moving beyond the traditional key card system. This is particularly beneficial for larger operations such as warehouses. Different employees need different levels of access for different areas, and different keys or key cards are used to open different doors and access points. In addition to being time consuming and inefficient, key cards do not offer the highest level of security as they can be lost, stolen, or duplicated. Using credentials like face recognition and mobile access are, however, a secure and convenient way to navigate through a secure facility.

Benefits of Modern Warehouse Access Control

By upgrading warehouse access control, security and operations are improved significantly:

- Eliminate the overhead from key cards and fobs

- Manage access points and access permissions remotely

- Grant and assign different levels of access to different users or user groups

- Audit warehouse access events, and view real-time events

- Upgrade from legacy systems, which require expensive maintenance, software upgrades, and technical training or assistance

Smart Packaging

Smart packaging has been steadily gaining popularity since 2012. Today, it’s a multi-billion dollar industry. But, what exactly is “smart packaging”?

The umbrella term smart packaging refers to two categories of enhanced packaging:

Active Packaging: Active packaging is a form of smart packaging that allows the packaging materials to control atmospheric conditions for the product, such as moisture control, oxygen control, and temperature control. For example, modified atmosphere packaging is an excellent example of active packaging.

Intelligent Packaging: Intelligent packaging is a form of smart packaging that provides data and status updates for the products within, including but not limited to the current location and quality.

Through the use and advancement of biosensors, printable electronics, and other related devices, intelligent packaging is primarily used to enhance food safety (although there are other applications). This is accomplished through the continual monitoring of the quality of food products via the technologies mentioned above.

The evolution in each of these technologies has resulted in better tracking and monitoring of the quality and current state of food products as they move throughout the supply chain.

Benefits of Smart Packaging in Warehouses

As the technological advancements that have allowed for the rise of smart packaging continue to evolve, these technologies remain essential to the continued evolution and improvement of modern warehousing capabilities.

The enhancements in safety, shipping, product status reports, and geo-location that smart packaging has to offer give the modern warehouse ecosystem the ability to run safer, more efficiently, and faster than ever before.

Additionally, the data that can be tracked with smart packaging provides businesses who choose to employ it another way to provide superior customer service to their clients via access to this information.

Warehouse Automation

IoT, or the internet of things, is the digitally connected network of physical objects that are embedded with technologies — printable electronics, sensors, and other forms of tech –intended for communications and data transfer with other digitally connected devices over the internet. And, it is playing a huge role in warehouse automation and management.

Labor: While many smart warehouses will still rely mainly on human labor, much of these responsibilities are being outsourced to machinery. In this way, warehouse automation allows employees to capitalize on their time for higher level work while other tasks are outsourced.

Hardware and Equipment: From inventory drones to autonomous forklifts and collaborative robots, IoT provides many opportunities to automate a company’s supply chain fully. The automation of hardware and equipment saves time and money by allowing those employees to better utilize their time on high-level tasks. It’s also safer to have less bodies navigating around and operating heavy machinery.

Logistics: In addition to increased hardware and equipment automation, IoT is also streamlining many aspects of logistics, including inventory management, vision picking, and data analytics. Through the use of warehouse management systems (WMS), managers can track and integrate data from the technologies mentioned above with information about tracking, documentation, and reporting features assessing overall warehouse efficiency. This lets managers quickly and easily produce in-depth reports, allowing the warehouse to improve upon key performance indicators continually. Regular improvements to KPIs translates to a warehouse that constantly improves upon every aspect of the supply chain.

When done correctly, IoT integration with warehousing results in bigger, better, faster, more efficient supply chain dynamics for those companies who choose to integrate these technologies into their warehousing management protocols.

AI-Powered Machine Vision

AI-powered machine vision or Vision AI (AKA Computer Vision) uses computer science technologies to develop artificial vision systems that replicate human vision capabilities. These artificial vision systems give digital equipment such as automatic thermal scanners, facial recognition devices, and label scanners the ability to “see” and analyze objects, QR codes, and other identifiers in a way similar to that of human beings.

Vision AI technology in warehouses allows warehouse managers or admins the ability to:

- Enhance quality control

- Improve accuracy and applicability of classification

- Improve real-time tracking capabilities

Altogether, vision AI is allowing warehouses to capitalize on their efficiency which fosters business continuity, drives profit, and reduces operational cost.