Welcome to our in-depth exploration of CSI Division 11 – Equipment specifications in the construction industry. In this comprehensive guide, I will walk you through the various aspects of CSI Division 11, from understanding its importance to mastering the specification process and keeping up with the latest industry trends. Whether you are an experienced professional or a newcomer to the construction industry, this guide will help you better understand the role of equipment in modern construction projects and how to stay updated with the latest technological advancements.

The construction industry is constantly evolving, and staying ahead of the curve is essential for ensuring the success of your projects. So, let’s get started!

- Section 1: Introduction to CSI Division 11 – Equipment

- Section 2: Specification Process for Division 11 Equipment

- Section 3: Key Components of CSI Division 11 – Equipment Specifications

- Section 4: Understanding Regulatory Compliance for Division 11 Equipment

- Section 5: Case Study: Successful Implementation of CSI Division 11 Equipment

- Section 6: Staying Current with Industry Trends and Advancements in CSI Division 11 Equipment

In this guide, we will dive deep into the importance of CSI Division 11 in the construction industry and its benefits for architects, engineers, and contractors. We will discuss the specification process for Division 11 equipment, including overcoming common challenges and ensuring a seamless specification process. We will also cover the essential elements of equipment specifications, such as product information, material selection, performance requirements, installation methods, and maintenance guidelines.

Additionally, we will delve into regulatory compliance and safety standards, providing insights on how to ensure your equipment meets necessary standards. Furthermore, we will present a real-world case study showcasing the successful implementation of CSI Division 11 equipment in a construction project. This case study will highlight the project’s challenges, solutions, and overall success, providing valuable lessons learned and recommendations for future projects.

Lastly, we will discuss the importance of staying current with industry trends and advancements in CSI Division 11 equipment technology. This guide will provide tips on staying informed and discuss the potential impact of emerging technologies on future construction projects and the evolution of equipment specifications. So let’s dive in and explore the fascinating world of CSI Division 11 – Equipment in the construction industry. Here’s to building better projects and a brighter future for our industry!

Suggested Posts:

Introduction to CSI MasterFormat and Division 01

Getting to Grips with CSI Division 02 – Existing Conditions in Construction Projects

Mastering Division 09 – Finishes in the CSI MasterFormat System for Improved Project Success

Understanding CSI MasterFormat: Division 14- Conveying Equipment

Master the Art of Utilities Construction with CSI Division 33

Division 48 – A Comprehensive Guide to Electrical Power Generation in Construction

Introduction to CSI Division 11 – Equipment

In this blog post, we will take a deep dive into CSI Division 11, exploring its importance, benefits, and the typical categories and subcategories you will find within the division. So, let’s dive in!

CSI Division 11 is an essential part of the construction industry, focusing on the equipment used in various construction projects. It plays a crucial role in ensuring the success of a project by outlining specific requirements, materials, and performance standards for equipment installations. This division helps architects, engineers, and contractors to streamline the specification process, maintain consistency across projects, and simplify coordination between different teams involved in the construction process. The importance of CSI Division 11 cannot be overstated as it provides numerous benefits to construction professionals, including:

Standardization: By complying with CSI Division 11, architects, engineers, and contractors can ensure that their projects meet industry standards and regulatory requirements.

Efficiency: This division helps professionals save time and resources by providing a systematic and organized approach to equipment specifications.

Quality control: Compliance with Division 11 helps construction professionals maintain quality control by outlining clear and concise specifications for equipment installations. Division 11 encompasses a wide range of equipment categories and subcategories designed to cater to specific construction project needs.

These categories include, but are not limited to:

11 10 00: Vehicle and Pedestrian Equipment

11 20 00: Commercial Equipment

11 30 00: Residential Equipment

11 40 00: Foodservice Equipment

11 50 00: Educational and Scientific Equipment

11 60 00: Entertainment Equipment

11 70 00: Healthcare Equipment

11 80 00: Collection and Disposal Equipment

11 90 00: Other Equipment

Each category and subcategory within CSI Division 11 serves a unique purpose in the construction process, ensuring that equipment installations meet specific project requirements and performance standards.

In conclusion, CSI Division 11 is an integral part of the construction industry, providing architects, engineers, and contractors with a framework to specify equipment requirements and ensure project success. By understanding its importance and the benefits it provides, construction professionals can make informed decisions when specifying equipment for their projects. Stay tuned for Section 2, where we will explore the specification process for Division 11 equipment in detail.

Specification Process for Division 11 Equipment

The specification process for Division 11 equipment plays a crucial role in ensuring the success of any construction project. This section aims to provide a step-by-step breakdown of the process, highlighting the importance of clear and concise specifications, common challenges faced by architects, engineers, and contractors, and tips to overcome these challenges and streamline the specification process.

Identify Project Requirements

The first step in the specification process involves developing a comprehensive understanding of the project’s requirements. This involves evaluating the functional needs, budget constraints, and overall timeline of the construction project. By clearly defining these factors, professionals can make informed decisions when specifying Division 11 equipment.

Conduct Research and Product Selection

Next, architects, engineers, and contractors should conduct thorough research to identify the most suitable equipment for the specific project. This includes evaluating product information, material selection, and performance requirements. By staying up-to-date with industry trends and advancements, professionals can ensure they are specifying the most efficient and cost-effective equipment available on the market.

Collaborate with Equipment Suppliers

Involving equipment suppliers early in the specification process can significantly improve the quality of the final product. By collaborating with suppliers, professionals can gain valuable insights into product features, installation methods, and maintenance guidelines, ensuring a seamless integration of Division 11 equipment into the construction project.

Develop Clear and Concise Specifications

Once the appropriate Division 11 equipment has been identified, it is essential to develop clear and concise specifications. By providing accurate and detailed information, architects, engineers, and contractors can minimize the risk of miscommunication and costly errors throughout the construction process.

Ensure Regulatory Compliance

As regulatory compliance and safety standards play a vital role in the construction industry, it is important to ensure that specified Division 11 equipment adheres to all relevant regulations. This includes working closely with equipment suppliers to obtain compliance documentation and ensure equipment meets necessary standards, such as OSHA, ANSI, and other industry codes. By prioritizing compliance, professionals can avoid potential fines, project delays, and safety hazards.

Monitor and Evaluate Equipment Performance

Lastly, it is crucial to monitor the performance of Division 11 equipment throughout the construction project. By conducting regular evaluations and addressing any issues that may arise, professionals can ensure the overall success of the project and the long-term durability of the equipment.

Overcoming Common Challenges

The specification process for Division 11 equipment can present various challenges, such as navigating product complexity, coordinating with multiple stakeholders, and responding to fluctuating project requirements. To overcome these challenges, professionals can adopt the following strategies:

- Develop a comprehensive understanding of project requirements and anticipate future needs

- Stay informed on industry trends and advancements in Division 11 equipment

- Collaborate closely with equipment suppliers for expert guidance and support

- Adopt effective communication strategies to minimize miscommunication and project delays

- Prioritize regulatory compliance and safety standards throughout the specification process

By following these tips, architects, engineers, and contractors can effectively navigate the specification process for Division 11 equipment, ensuring the success of their construction projects.

Key Components of CSI Division 11 – Equipment Specifications

When it comes to specifying equipment within CSI Division 11, it is crucial to have a clear understanding of the essential elements that must be included in the specifications. These key components ensure that the selected equipment aligns with the specific project needs and goals. In this section, we will discuss the following critical components of equipment specifications: product information, material selection, performance requirements, installation methods, and maintenance guidelines.

Product Information

At the core of any equipment specification is the product information. This includes a detailed description of the equipment, its purpose, and its features. It is essential to provide accurate and clear information about the equipment to enable architects, engineers, and contractors to make informed decisions about the appropriateness of the product for the project.

Material Selection

Closely related to product information is the selection of materials that make up the equipment. Material selection is vital for ensuring the equipment meets the desired quality, durability, and performance standards. The chosen materials should be based on the specific needs of the project and the environment in which the equipment will be installed and operated.

Performance Requirements

Performance requirements are another essential component of CSI Division 11 equipment specifications. These requirements outline the desired operation and performance outcomes of the equipment, such as capacity, energy efficiency, and safety features. By including specific and measurable performance requirements within the specifications, project teams can effectively evaluate and compare equipment options.

Installation Methods

The installation methods are a critical aspect of ensuring the proper functioning and longevity of the equipment. These methods should provide clear instructions on how to safely and effectively install the equipment, taking into consideration any specific project or site constraints. Proper installation is crucial for reducing the risk of equipment failure or damage and ensuring the equipment performs as intended.

Maintenance Guidelines

Lastly, the specifications should include comprehensive maintenance guidelines for the equipment. These guidelines should outline the recommended maintenance procedures and schedules to ensure the equipment continues to operate efficiently and safely throughout its lifecycle.

By following these guidelines, building owners and operators can reduce the risk of equipment failure, extend the equipment’s lifespan, and maintain optimal performance. In conclusion, a well-crafted CSI Division 11 equipment specification should include detailed product information, appropriate material selection, clearly defined performance requirements, proper installation methods, and comprehensive maintenance guidelines.

By addressing these key components within the specifications, architects, engineers, and contractors can ensure they select the right equipment for their specific project needs, ultimately contributing to the overall success of the construction project.

Understanding Regulatory Compliance for Division 11 Equipment

When specifying and implementing equipment in CSI Division 11, it’s crucial to be aware of the various regulatory compliance and safety standards that apply to the construction industry. Adhering to these regulations not only ensures the safety and well-being of workers and end-users but also helps avoid potential legal issues and penalties.

In this section, we will delve into the importance of following these regulations, provide an overview of common compliance standards, such as OSHA, ANSI, and other relevant industry codes, and discuss how to obtain compliance documentation and ensure equipment meets necessary standards.

Compliance Standards

There are several regulatory bodies and industry standards that apply to equipment in CSI Division 11. Some of the most common compliance standards include:

- Occupational Safety and Health Administration (OSHA): OSHA regulates workplace safety and has specific standards for equipment in the construction industry. These standards cover a wide range of topics, including machine guarding, fall protection, electrical safety, and more.

- American National Standards Institute (ANSI): ANSI oversees the development of voluntary consensus standards for many industries, including construction. It also accredits organizations that develop standards and certify products, ensuring that they meet the necessary requirements.

- Industry Codes: Various industry-specific codes govern the design, construction, and maintenance of equipment in Division 11. These codes may differ depending on the jurisdiction, but some examples include the International Building Code (IBC), National Electric Code (NEC), and American Concrete Institute (ACI) standards.

Obtaining Compliance Documentation

Before purchasing or specifying Division 11 equipment, it’s essential to verify that it complies with the required standards. Manufacturers and suppliers should be able to provide compliance documentation, such as test reports, certifications, and product literature. This documentation can also be helpful for building inspectors, facility managers, and other stakeholders during the construction process.

Ensuring Equipment Meets Standards

To ensure that the selected equipment meets the necessary compliance standards, consider the following steps:

- Thoroughly review product specifications and compliance documentation: This will help you understand the equipment’s performance characteristics and confirm that it meets the required standards.

- Consult with industry experts: Seek guidance from industry experts, such as engineers, architects, and code officials, regarding the specific equipment and its regulatory compliance.

- Perform on-site inspections: Regularly inspect the equipment during installation and throughout the project to ensure that it remains compliant and functions as intended.

- Stay informed about updates to regulations: Regulatory requirements and industry standards can change over time, so it’s crucial to stay current with the latest updates to ensure ongoing compliance.

Understanding and adhering to regulatory compliance and safety standards for equipment in CSI Division 11 is essential for successful construction projects. By thoroughly reviewing product specifications, obtaining compliance documentation, and consulting with industry experts, you can ensure that your equipment meets all necessary standards, ultimately promoting safety and project success.

Case Study: Successful Implementation of CSI Division 11 Equipment

In this section, we will explore a real-world case study of a construction project that successfully implemented equipment from CSI Division 11. This case study will serve as an excellent example of overcoming challenges associated with specifying, procuring, and installing Division 11 equipment while meeting project requirements and maintaining compliance with industry standards.

Project Overview

The project involved the construction of a large-scale sports complex featuring multiple venues, including an indoor basketball court, a swimming pool, a fitness center, and several multipurpose halls. The budget was $25 million, and the project duration was 18 months. As a result, the team faced several challenges, including tight deadlines, a rigorous regulatory environment, and the need for high-performance equipment across all venues.

Challenges and Solutions

- Clear and concise specifications: The first challenge was to ensure clear and concise specifications for all Division 11 equipment. To overcome this challenge, the project team engaged an experienced construction specification expert who provided detailed product information, material selection, performance requirements, installation methods, and maintenance guidelines.

- Regulatory compliance: The project had to comply with various safety standards, such as OSHA, ANSI, and other relevant industry codes. To ensure compliance, the team worked with equipment manufacturers who provided the necessary documentation and certifications demonstrating that their products met the required standards.

- Coordinating with multiple stakeholders: The project involved working with architects, engineers, contractors, and equipment suppliers, which required effective communication and collaboration. The project team held regular meetings and used cloud-based collaboration tools to keep everyone informed and aligned throughout the construction process.

- Sourcing high-quality equipment: The team also faced the challenge of sourcing high-quality, reliable equipment within the project budget. To overcome this challenge, they researched, reviewed, and compared equipment from various vendors using a well-defined evaluation process that focused on performance, durability, and value for money.

Impact on Project Success

The successful implementation of CSI Division 11 equipment played a crucial role in the overall success of the sports complex construction project. Key benefits included:

- Enhanced performance: The high-quality equipment specified and procured for the project allowed users to enjoy superior performance across all venues, ensuring a positive experience for athletes and spectators alike.

- Safety and compliance: By adhering to industry standards and regulations, the project team ensured that all venues were safe for users, minimizing the risk of accidents and legal liabilities.

- Cost savings: The comprehensive equipment specification process resulted in significant cost savings, as the project team identified equipment that offered excellent value for money without compromising on performance or durability.

Lessons Learned and Recommendations

This case study demonstrates the importance of carefully specifying, sourcing and installing CSI Division 11 equipment in construction projects. Key lessons learned include:

- Engage an experienced construction specification expert to ensure clear and concise specifications for all Division 11 equipment.

- Prioritize regulatory compliance and work closely with equipment manufacturers to obtain the necessary documentation.

- Foster effective communication and collaboration among all project stakeholders.

- Adopt a comprehensive evaluation process for sourcing high-quality equipment within the project budget.

By following these recommendations, future construction projects can successfully implement CSI Division 11 equipment while maximizing performance, safety, and cost-effectiveness.

Have Questions?

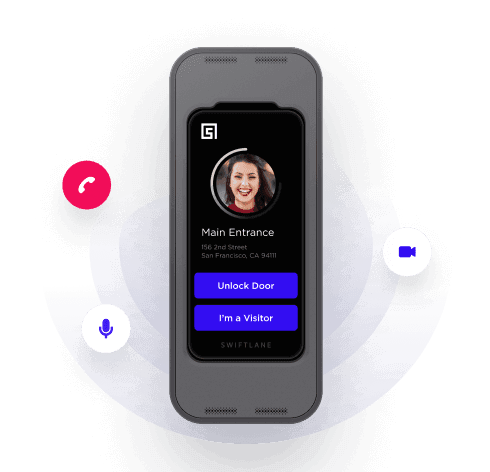

Get in touch with our team to learn more about what Swiftlane can do for you.