In today’s rapidly evolving construction industry, staying organized and efficient is more critical than ever. One key tool that helps the industry maintain consistency and organization is the Construction Specifications Institute (CSI) MasterFormat system. This essential classification method covers thousands of building materials, products, and processes, ensuring that professionals can easily communicate and coordinate throughout the construction process. In this blog post, we’ll be diving into one specific and vital aspect of the MasterFormat system: Division 14 – Conveying Equipment.

Table of contents

- The Significance of Division 14- Conveying Equipment

- Division 14: What Is Conveying Equipment?

- Key Components of Conveying Equipment

- Types of Conveying Equipment in Division 14

- Selecting the Right Conveying Equipment

- Sector-specific Applications of Conveying Equipment

- Regulations and Standards for Division 14 Equipment

- Maintenance and Safety Considerations: The Key to Reliability and Longevity

- The Future of Conveying Equipment: Emerging Technologies and Trends

Suggested Posts:

- A Closer Look: The Future of Apartments

- Introduction to CSI MasterFormat and Division 01

- Choosing a Commercial Real Estate Access Control System

- Mastering Division 09 – Finishes in the CSI MasterFormat System for Improved Project Success

The Significance of Division 14- Conveying Equipment

Conveying equipment plays a crucial role in building operations by transporting people, goods, and materials between floors, rooms, or even buildings. These systems ensure the smooth functioning of a structure and enhance its overall efficiency, accessibility, and safety. By dedicating a specific division to conveying equipment within the MasterFormat system, industry professionals can stay organized and collaborate effectively when designing, installing, and maintaining these essential systems.

Division 14: What Is Conveying Equipment?

In the world of construction, the term “conveying equipment” refers to a wide range of systems that are designed to transport people, goods, and materials within buildings or between various locations. These systems play a critical role in ensuring smooth and efficient building operations, contributing to a better overall experience for occupants and visitors.

Key Components of Conveying Equipment

Conveying equipment is more than just a means to get material from one point to another; it’s a critical component in the overall functionality of a structure. Here are some essential features of conveying equipment:

- Accessibility: Conveying systems, such as elevators, provide access to different floors, making it easier for individuals with mobility challenges to navigate the building.

- Efficiency: By improving the flow of goods and materials throughout a building, conveying equipment can help reduce the time spent on manual labor, increase productivity, and optimize space utilization.

- Safety: Properly designed and maintained conveying equipment can help minimize the risk of accidents, ensuring a safer environment for all occupants. In summary, conveying equipment in construction is all about enhancing the overall experience within buildings while balancing accessibility, efficiency, and safety. By understanding the purpose and significance of Division 14, professionals can better design and implement these crucial systems in their projects.

Types of Conveying Equipment in Division 14

Conveying equipment comes in various forms, each designed to suit specific needs and applications. Let’s explore some of the key types of conveying equipment and systems that fall under Division 14.

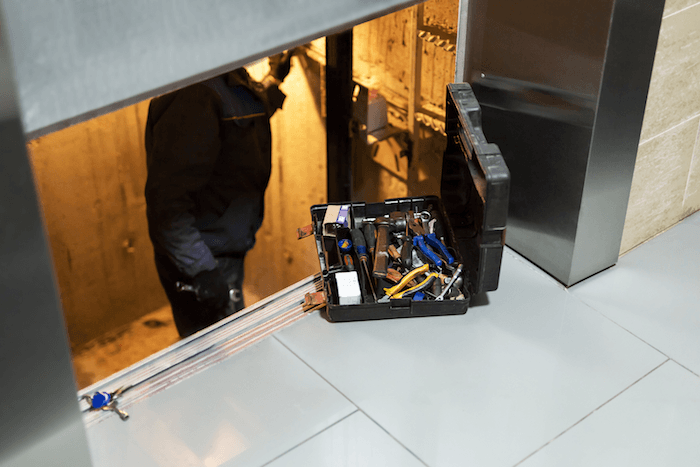

Elevators

One of the most common and essential conveying equipment, elevators are vertical transportation systems that move people and goods between floors in multi-story buildings. They come in different types, such as:

- Passenger elevators: Designed for transporting people, these elevators prioritize comfort and speed.

- Freight elevators: Built for carrying heavy loads, they feature durable materials and robust design.

- Service elevators: Used by maintenance staff, these elevators typically have restricted access and may include additional utility features.

Escalators and Moving Walkways

These horizontal and inclined conveying systems are widely used in public and open spaces such as malls, airports, and transit stations. Key types include:

- Escalators: They provide a continuous, inclined transport for passengers, typically connecting consecutive floors.

- Moving walkways: Also known as travelators, these horizontal conveyors help passengers traverse long distances with minimal effort.

Additional Conveying Equipment

Division 14 also encompasses other conveying systems such as:

Dumbwaiters: Small, contained lifts used to transport goods between floors, often found in restaurants or hospitals.

Vertical platform lifts: Designed to accommodate wheelchairs, they provide accessibility for people with mobility challenges.

Material lifts: These systems are used to transport equipment, inventory, and raw materials in industrial settings. By understanding the various types of conveying equipment in Division 14, building professionals can choose the right systems for their specific projects and ensure efficient, safe, and accessible transportation solutions.

Selecting the Right Conveying Equipment

Choosing the perfect conveying equipment for your building project is a crucial step in ensuring safety, efficiency, and cost-effectiveness. Keep the following tips in mind when selecting the best solution for your needs:

Assess Your Requirements

- Building size and layout: Consider the overall height and floor plan, ensuring the conveying system fits comfortably without impeding other essential spaces.

- Capacity and usage: Estimate the number of users and the expected transportation frequency to determine the right size and speed for your conveying equipment.

Evaluate Safety and Efficiency

- Compliance with regulations: Ensure the equipment adheres to local construction codes and safety standards.

- Energy efficiency: Select systems with optimal power consumption to reduce environmental impact and long-term operational costs.

Consider Cost-Effectiveness and Maintainability

- Budget restrictions: Weigh the initial investment against long-term benefits, such as energy savings and reduced maintenance needs.

- Ease of maintenance: Opt for equipment with accessible components and comprehensive support services to minimize downtime and maintenance costs. By carefully evaluating your project requirements and weighing the various factors, you can select the right conveying equipment that ensures safety, efficiency, and cost-effectiveness in your building.

Sector-specific Applications of Conveying Equipment

Different industries and building types have unique requirements when it comes to conveying equipment. Below, we’ll explore some of the key sectors that rely on various conveying systems and their site specific considerations:

Healthcare Facilities

Hospitals and medical centers have stringent requirements for accessibility and hygiene. The conveying equipment used in these settings should:

- Be easy to clean and maintain

- Accommodate patients with mobility issues, such as wheelchairs and stretchers

- Provide quick and efficient transportation

Hospitality and Resorts

Hotels, resorts, and other luxury establishments prioritize comfort and aesthetics in their conveying equipment. Key aspects include:

- Smooth and quiet operation for guest satisfaction

- Elegant design to blend seamlessly with the overall architecture and decor

Manufacturing and Warehouses

In these settings, the primary focus is on material handling and efficient transportation. Conveying systems should:

- Be tough and durable to handle heavy loads

- Optimize the movement of goods and materials throughout the facility

Public Transportation Hubs

Airports, train stations, and bus terminals require conveying equipment designed for high volume usage and ease of maintenance. Considerations include:

- Capacity to handle a large number of passengers simultaneously

- Robust design for minimal downtime and maintenance needs In conclusion, understanding the specific needs of different sectors helps professionals select the appropriate conveying equipment, ensuring efficient and safe transportation solutions tailored to each industry’s unique requirements.

Regulations and Standards for Division 14 Equipment

When it comes to the installation and use of conveying equipment, strict regulations and standards are in place to ensure safety and quality. These measures encompass a variety of aspects, from design and manufacturing to installation and maintenance. Let’s take a look at some key regulatory bodies and standards that govern Division 14 equipment:

ASME A17.1/CSA B44: Safety Code for Elevators and Escalators

This North American standard defines the safety requirements for the design, construction, installation, and maintenance of elevators, escalators, and other conveying equipment. Key aspects include:

- Requirements for operational safety and performance

- Guidelines for emergency procedures

- Regular inspection and testing provisions

EN 81 Series: European Standards for Elevators and Escalators

These European standards address similar aspects as the ASME A17.1/CSA B44 with a focus on the European market. The series covers various types of elevators and escalators, ensuring their safe and efficient operation within the region.

Local Building Codes and Regulations

In addition to international standards and specifications, conveying equipment must also adhere to local building codes and regulations. These rules may vary by region or country, influencing factors such as:

- Load-bearing capacity

- Fire safety measures

- Accessibility requirements for individuals with disabilities Understanding and complying with these regulations and standards is essential for ensuring safety and quality in Division 14 equipment throughout its lifespan.

Maintenance and Safety Considerations: The Key to Reliability and Longevity

Proper maintenance and regular safety checks of conveying equipment are crucial aspects that should never be overlooked. Implementing a consistent upkeep routine ensures the reliability and longevity of these systems, preventing accidents and costly downtime due to breakdowns. Here’s why this aspect is so important:

Safety First: Preventing Accidents and Ensuring Compliance

- Regular inspections and maintenance help identify potential hazards, such as worn components or malfunctioning safety systems, before they lead to accidents.

- Staying up-to-date with safety regulations and industry standards ensures compliance and a safer environment for all occupants.

Minimizing Downtime: Keeping Your Conveying Equipment in Top Shape

- Timely maintenance helps avoid unexpected breakdowns, reducing the burden on other systems and minimizing disruptions to building operations.

- A well-maintained conveying system is more energy-efficient, translating to cost savings and a reduced environmental impact.

Smart Maintenance: Establishing a Routine and Embracing Innovation

- A preventive maintenance schedule, tailored to each equipment type and usage, helps identify and resolve issues before they escalate.

- Embracing innovative maintenance technologies, such as remote monitoring and smart sensors, can further streamline upkeep efforts and enhance overall system performance.

In conclusion, prioritizing maintenance and safety considerations for conveying equipment is vital to ensure a safe, efficient, and cost-effective transportation solution within your building.

The Future of Conveying Equipment: Emerging Technologies and Trends

As we look towards the future, the conveying equipment industry is poised for exciting innovations that will reshape the way we think about transportation within buildings. Let’s explore some of the key technologies and trends shaping the future of Division 14 equipment:

- Smart conveyance systems: Advanced sensor technologies and Internet of Things (IoT) connectivity will enable conveying systems to communicate with one another, optimizing routes and reducing wait times for passengers.

- Energy efficiency: With an increasing focus on sustainability, the development of energy-efficient conveying equipment is likely to surge. Innovations such as regenerative drives and solar-powered escalators will pave the way for eco-friendly transport solutions.

- Biophilic design: As more buildings incorporate biophilic design principles to enhance wellbeing, conveying equipment will showcase elements of nature, such as green walls and natural light, creating a more pleasant experience for users.

- Customization and personalization: With advancements in manufacturing technologies, like 3D printing and modular designs, conveying equipment will be tailored to fit specific building requirements and unique aesthetic preferences. These emerging technologies and trends illustrate that the future of conveying equipment is both exciting and promising, ultimately enhancing building experiences for occupants and visitors alike.

Conclusion

As we’ve examined the intricacies of Division 14 – Conveying Equipment, it becomes clear that these systems are integral for efficient, safe, and accessible operations within diverse building environments. From understanding various conveying equipment types, to acknowledging sector-specific applications and adhering to stringent regulations, professionals can make informed decisions that cater to unique project needs. Future advancements in this field, such as smart systems, energy efficiency, and personalized designs, signal exciting possibilities for further enhancing building experiences. Embracing these developments while prioritizing regular maintenance and safety will ensure reliable and cost-effective conveying solutions that meet the evolving demands of the construction industry.

Have Questions?

Get in touch with our team to learn more about what Swiftlane can do for you.