Welcome to our comprehensive guide to concrete in construction! Concrete, a vital component of the construction industry, is more than just a mixture of cement, water, and aggregate. Its incredible versatility and adaptability have made it a key player in sustainable construction and green building practices.

In this blog post, we will delve into all aspects of concrete, from Construction Specifications Institute (CSI) Division 03 classification to the latest innovations in concrete technology. By the end of this post, you’ll be well-versed in the types of concrete, mix design, placement methods, and common issues and solutions. Throughout this guide, we’ll be covering the following topics in depth:

- CSI Division 03: Concrete in Construction

- Components and types of concrete

- Concrete mix design and quality control

- Concrete placement, curing, and finishing

- Common concrete issues and solutions

- Future trends and innovations in concrete technology

Our aim is to provide you with a thorough understanding of concrete’s role in the construction industry, as well as the ability to make informed decisions when it comes to specifying, designing, and applying concrete in your projects.

Whether you’re a seasoned construction professional or just starting on your journey in the industry, there is always something new to learn about this versatile material. So, let’s dive into the world of concrete and explore its limitless possibilities. Stay tuned for our first section, where we’ll introduce CSI Division 03 and discuss the importance of concrete in modern construction.

With a focus on sustainability, we’ll also touch upon the role of concrete in green building practices. Get ready to embark on an exciting journey through the world of concrete, as we uncover its many facets and applications in the construction domain.

Suggested Posts:

Introduction to CSI MasterFormat and Division 01

Mastering Division 09 – Finishes in the CSI MasterFormat System for Improved Project Success

Understanding CSI MasterFormat: Division 14- Conveying Equipment

Introduction to CSI Division 03-Concrete

CSI Division 03, also known as the concrete division, covers the use and implementation of various concrete materials, reinforcement, and techniques used in the construction industry. It is a crucial part of the building process due to the versatility, durability, and strength of concrete.

Concrete serves as the backbone of most modern structures, ranging from residential buildings and commercial establishments to infrastructure projects such as bridges, highways, and dams. One of the most significant advantages of concrete in construction is its adaptability to various applications and environmental conditions. This adaptability is due to the numerous components, types, and mix designs of concrete that can be tailored to meet the specific requirements of a project. Apart from its strength and versatility, concrete has also become a vital component in sustainable construction and green building practices. With advancements in eco-friendly cement alternatives, recycled aggregates, and energy-efficient production methods, concrete is paving the way for a more sustainable future in the construction industry.

In the following sections, we will dive deeper into the world of concrete and explore the components, types, mix designs, quality control, and common issues faced in concrete applications. Furthermore, we will look at the latest trends and innovations in concrete technology, with a focus on sustainability and green building practices. So, without further ado, let’s embark on this journey to better understand the importance of concrete in the construction industry and how it impacts our modern world.

Components and Types of Concrete

In the world of construction, concrete is one of the most versatile and widely used materials. From building foundations to sidewalks and skyscrapers, concrete plays an integral role in creating durable and long-lasting structures. In this section, we will delve into the various components and types of concrete used in construction projects.

Components of Concrete

The primary ingredients in concrete are Portland cement, water, aggregate, admixtures, and reinforcement elements. The mixture of these components determines the properties and characteristics of the final concrete product. Let’s briefly examine each component:

- Portland cement: This is the primary binding agent in concrete that hardens and gives strength to the mixture. Portland cement is made from limestone, clay, and other additives, which are heated and ground together to form a fine powder.

- Water: Water is necessary to initiate the chemical reaction between cement and other ingredients. The appropriate amount of water is crucial, as too much or too little can affect the concrete’s strength and workability.

- Aggregate: These are granular materials, such as sand, gravel, and crushed stone, that make up the bulk of the concrete mixture. Aggregate strengthens the concrete, reduces shrinkage, and lowers the cost of the final product.

- Admixtures: Additives are used to modify the properties of concrete, such as its workability, strength, and durability. Common admixtures include accelerators, retarders, air-entraining agents, and water-reducing agents.

- Reinforcement elements: Concrete is strong in compression but weak in tension. To overcome this limitation, steel bars or fibers are often incorporated into the concrete mix to provide tensile strength and increase its load-bearing capacity.

Types of Concrete

There is a wide range of concrete types designed for various applications, depending on the desired characteristics and performance requirements. Some common types of concrete include:

- High-strength concrete: This type of concrete has a compressive strength of over 6,000 psi (pounds per square inch), making it ideal for load-bearing structures and heavy-duty applications.

- Lightweight concrete: As the name suggests, lightweight concrete uses lightweight aggregates (such as expanded clay or shale) to reduce its overall weight. This type of concrete is often used in high-rise buildings and bridges due to its reduced weight and improved thermal insulation properties.

- Self-consolidating concrete: Also known as self-leveling concrete, this type of concrete is designed to flow and spread easily, filling in gaps and spaces without the need for mechanical vibration. This is particularly useful in complex or congested areas where traditional compaction methods may be challenging.

In conclusion, understanding the components and various types of concrete is essential for industry professionals who rely on this versatile material for a wide range of construction projects. With so many possibilities and combinations, concrete will continue to be a cornerstone of modern construction for the foreseeable future.

Concrete Mix Design and Quality Control

In the world of construction, concrete is an essential material that needs to meet specific requirements and project specifications. In this section, we will discuss the process of concrete mix design and the importance of quality control during concrete production and placement.

Understanding Concrete Mix Design

Concrete mix design is a critical process that involves determining the right proportions of ingredients, such as Portland cement, water, aggregate, and admixtures, to achieve the desired workability, strength, durability, and cost-effectiveness of the concrete. Factors that influence mix design decisions include:

- The intended application of the concrete (e.g., foundations, walls, or slabs)

- Environmental conditions and exposure of the concrete to various elements (e.g., chemical attacks, freeze-thaw cycles, or abrasion)

- Required strength and durability for the project

- Local availability and cost of materials

Engineers and technicians use various methods and guidelines, based on the project-specific requirements, to calculate the optimal mix proportions. The goal is to develop a robust and efficient concrete mix design that meets the necessary performance criteria while considering cost implications and ease of construction.

Importance of Quality Control in Concrete Production

Quality control is a fundamental aspect of concrete production and placement. To ensure that the concrete meets the project specifications, it is crucial to monitor and maintain consistency during the entire production process. This includes:

- Inspection and verification of raw materials (e.g., cement, aggregates, and admixtures)

- Monitoring and adjusting the batching, mixing, and transportation of concrete

- Implementing testing methods on fresh and hardened concrete to evaluate properties such as workability, compressive strength, and durability

Some common testing methods include slump tests, air content tests, and compression tests, which are essential for assessing the quality of the concrete and providing assurance that it will meet the required performance standards. Additionally, proper documentation of quality control procedures, test results, and any adjustments made to the mix design are vital. This information can serve as a reference in case of future disputes or issues related to the performance of the concrete.

Quality Control during Concrete Placement

During the concrete placement process, certain precautions and procedures must be followed to ensure that the concrete meets the project specifications. These include:

- Selection and preparation of appropriate formwork and reinforcement

- Using suitable placement and consolidation techniques, tailored to the project type and site conditions

- Ensuring proper curing methods are followed to maximize the development of strength and durability

Adherence to these guidelines is crucial for maintaining the structural integrity, functionality, and aesthetics of the finished concrete structure. In conclusion, concrete mix design and quality control play a significant role in guaranteeing the desired performance of concrete in construction projects.

Understanding the various factors that influence mix design and implementing rigorous quality control measures are essential for delivering a successful project that meets the required specifications. In the next section, we will discuss the different methods and equipment used for concrete placement, as well as the importance of proper curing and finishing techniques. Stay tuned for valuable insights that will help you excel in the world of construction and concrete production.

Concrete Placement, Curing, and Finishing

Through this blog post, we cannot stress enough the importance of proper concrete placement, curing, and finishing. These processes play a crucial role in ensuring that the concrete reaches its full potential in terms of strength, durability, and visual appeal. In this section, we will dive deeper into each of these processes and discuss best practices for optimally executing them.

Concrete Placement: The Foundation of a Successful Project

Concrete placement is the process of transferring mixed concrete from the mixing plant to the construction site and positioning it according to the project specifications. There are several methods and equipment used for this purpose, including:

- Pouring: A straightforward method involving transferring the concrete mixture directly from the truck mixer to the formwork.

- Pumping: Utilizing specialized machinery to pump the concrete through hoses or pipelines into the desired location.

- Conveying systems: Using conveyor belts or bucket systems to transport and place the concrete.

Proper concrete placement is vital for ensuring that the concrete uniformly fills the formwork and adequately surrounds all reinforcement elements. Additionally, it’s essential to pay attention to factors such as the weather, as extreme temperatures can affect the workability of the concrete mixture, compromising its long-term performance.

Curing: The Key to Concrete’s Strength and Durability

Curing is the process of maintaining the appropriate temperature and moisture levels during the hardening of concrete, allowing it to develop the necessary strength and durability. There are various curing methods available, such as:

- Water curing: Continuously spraying or ponding water on the concrete surface.

- Moisture-retaining coverings: Wrapping the concrete in plastic sheets or using wet burlap to maintain moisture levels.

- Chemical curing compounds: Applying a spray-on liquid membrane that retains moisture within the concrete.

It’s essential to be cautious during the curing process, as improper techniques can lead to issues such as weak or brittle concrete, or surface defects and cracking. Monitoring the curing process and addressing any issues promptly can ensure that the concrete achieves optimal strength and durability.

Finishing: Achieving the Desired Appearance and Texture

Concrete finishing is the process of creating a specific surface appearance and texture on the concrete. Depending on the project requirements, various techniques can be implemented:

- Troweling: Smoothing the concrete surface using a hand or power trowel.

- Brooming: Creating a slip-resistant texture by dragging a broom across the concrete surface.

- Stamping: Applying a pattern or texture to the concrete using specialized stamps or mats.

- Polishing: Grinding and polishing the concrete surface to achieve a glossy, reflective finish.

Selecting the appropriate finishing technique and executing it correctly is crucial for achieving the desired aesthetic appeal and ensuring that the concrete surface is both functional and visually appealing.

In conclusion, understanding the importance of proper concrete placement, curing, and finishing is vital for ensuring that your construction project meets its specifications and achieves the desired strength, durability, and aesthetic appeal.

Common Concrete Issues and Solutions

Concrete, being a go-to choice for various construction projects, isn’t without its share of challenges. Understanding the potential concrete issues and their respective solutions can prevent costly repairs and ensure the structural integrity and aesthetic appeal of your construction projects. In this section, we will delve into some common concrete problems, their causes, and the possible ways to avert or fix them.

Cracking

One of the most common issues associated with concrete is cracking. Cracks may occur for various reasons, including:

- Excessive water in the mix

- Rapid drying of the concrete

- Insufficient control joints

- Thermal changes

- Structural overload

Solutions: To prevent cracking, ensure that the concrete mix design is optimized with the right amount of water and admixtures. Proper curing practices, including maintaining moisture levels, can help avoid rapid drying. Incorporate control joints at the recommended spacing to accommodate concrete expansions and contractions. Additionally, consider using reinforcement elements, like steel bars or fibers, to enhance the concrete’s tensile strength.

Shrinkage

Shrinkage is another prevalent issue in concrete structures, which can lead to cracking, deformation, and reduced strength. Factors causing shrinkage include:

- Excessive water content

- High cement content

- Rapid drying conditions

- Coarse aggregate type and volume

Solutions: To mitigate shrinkage, monitor the water-cement ratio closely to reduce the potential for drying shrinkage. Opt for a low-shrinkage aggregate and consider incorporating shrinkage-reducing admixtures in the concrete mix. Furthermore, proper curing techniques can help control shrinkage and prevent potential issues in the concrete structure.

Discoloration

Discoloration is a concern that affects the appearance of concrete surfaces. Common causes of discoloration include:

- Variations in cement type, color, or shade

- Inconsistent water-cement ratios

- Irregular finishing and curing practices

- Weather conditions, such as excessive heat or cold

Solutions: Maintain uniformity of materials and mix proportions throughout the entire project to minimize discoloration. Use admixtures to control set times and use consistent finishing and curing practices. Additionally, consider using color-corrective techniques, such as chemical stain removers, to address any existing discoloration.

In conclusion, understanding the root causes of common concrete issues and implementing preventive measures are critical to maintaining the structural integrity and aesthetic appeal of your construction projects. As a construction specification expert, staying up-to-date with effective solutions and techniques will enable you to successfully navigate and resolve potential concrete issues.

Conclusion

In conclusion, this blog post provides a comprehensive exploration of the diverse world of concrete and its pivotal role in the construction industry. Covering everything from the components and types of concrete to its mix design, placement, curing, and finishing processes, it offers essential insights for industry professionals and novices alike. In the context of CSI Division 03, it underscores the adaptability and versatility of concrete, as well as its contribution to sustainable construction and green building practices.

Moreover, the post accentuates the importance of meticulous quality control at every stage of concrete production and placement, highlighting the need for consistency, thorough testing, and detailed documentation. The guidelines provided for concrete placement, curing, and finishing not only ensure the desired strength, durability, and aesthetic appeal but also contribute to the overall success of construction projects. Whether you’re a seasoned professional or just beginning your journey in the construction industry, the knowledge gleaned from this guide can empower you to make informed decisions about specifying, designing, and applying concrete in your projects.

Have Questions?

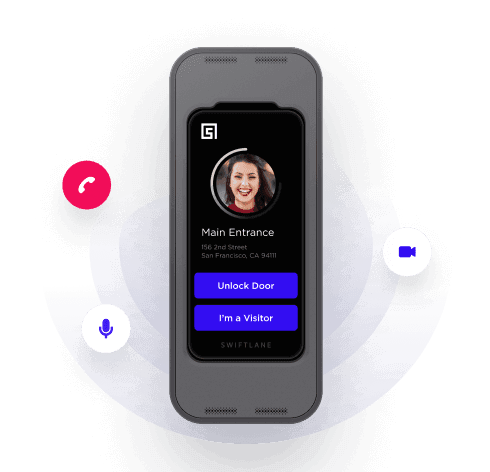

Get in touch with our team to learn more about what Swiftlane can do for you.