Welcome to our comprehensive guide on CSI Division 46, where we take you on a journey through the world of water and wastewater equipment. This essential guide will cover everything you need to know about this crucial aspect of the construction industry, ensuring that you stay up-to-date with the latest advancements and best practices. From the key components of water and wastewater treatment systems to the most innovative technologies shaping our industry, we’ve got you covered. If you’re a construction professional it’s pivotal that you understand the intricate details of Division 46, including its subcategories, equipment requirements, and maintenance procedures. With the increasing emphasis on sustainable construction and efficient resource management, this knowledge is more critical than ever to help you make informed decisions and excel in your field.

In this in-depth guide, we will cover:

- Introduction to CSI Division 46 – Water and Wastewater Equipment

- Key Components of Water Treatment Equipment

- Key Components of Wastewater Treatment Equipment

- Latest Technologies and Innovations in Water and Wastewater Equipment

- Maintenance and Troubleshooting of Water and Wastewater Equipment

- Conclusion and Future Outlook of CSI Division 46 – Water and Wastewater Equipment

Suggested Posts:

Unraveling CSI Division 32 – Welcome to the World of Exterior Improvements

Getting to Grips with CSI Division 02 – Existing Conditions in Construction Projects

Mastering Division 09 – Finishes in the CSI MasterFormat System for Improved Project Success

Introduction to CSI Division 46 – Water and Wastewater Equipment

Understanding Division 46 is critical for construction specification experts to ensure the proper selection, installation, and maintenance of these systems. The Construction Specifications Institute (CSI), a leading organization in the construction industry, introduced Division 46 to create a standardized framework for water and wastewater treatment processes. The division covers a broad range of equipment, including pumps, filters, and control systems, necessary for efficient water treatment and wastewater management.

Subcategories within Division 46

Division 46 consists of several subcategories, each focusing on specific aspects of water and wastewater equipment. These subcategories include:

- 46 01 00: Operation and Maintenance of Water and Wastewater Equipment

- 46 07 00: Water and Wastewater Equipment Accessories

- 46 11 00: Facility Water Treatment Equipment

- 46 21 00: Wastewater Preliminary Treatment Equipment

- 46 25 00: Wastewater Primary Treatment Equipment

- 46 31 00: Wastewater Secondary Treatment Equipment

- 46 43 00: Tertiary Wastewater Treatment Equipment

- 46 53 00: Water and Wastewater Residuals Equipment

Evolution of Division 46

With the advancements in the water and wastewater treatment sector, Division 46 has evolved to accommodate cutting-edge technologies and innovative solutions. Today, the division incorporates advanced equipment, such as intelligent water systems, membrane bioreactors, and ultraviolet disinfection systems, allowing for more efficient and sustainable water and wastewater treatment processes.

In the following sections, we will delve into the key components of water and wastewater equipment, explore the latest technologies and innovations, discuss the importance of maintenance and troubleshooting, and provide a future outlook for CSI Division 46. Stay tuned to gain valuable insights into this important aspect of the construction industry!

Key Components of Water Treatment Equipment

Water treatment is a crucial aspect of modern-day construction projects, ensuring clean, safe, and usable water supply in residential, commercial, and industrial developments. In this section, we will examine the key components of water treatment equipment and their significant role in the primary, secondary, and tertiary treatment processes.

Primary Treatment Equipment

The primary treatment phase involves the removal of large solids and suspended particles from the water. Key equipment used in this stage includes:

Sedimentation tanks: These tanks allow suspended particles to settle and be separated from the water through the process of gravity.

Clarifiers: These devices facilitate the settling of solid particles, typically using inclined plates or tube settlers to enhance the sedimentation process.

Secondary Treatment Equipment

Secondary treatment focuses on the removal of dissolved organic matter and nutrients, primarily through biological processes. Equipment involved in this stage includes:

Aeration systems: These provide oxygen to facilitate the growth of microorganisms, which break down organic matter in the water.

Activated sludge systems: These systems use microorganisms to metabolize and remove organic matter from the water.

Biofilters: These filters consist of a layer of microorganisms that break down organic material as water passes through them.

Tertiary Treatment Equipment

The tertiary treatment process focuses on the removal of any remaining impurities, such as pathogens or specific contaminants, to ensure the treated water meets the required quality standards. This stage involves the following equipment:

Sand filters: These remove any remaining suspended particles in the water.

Disinfection systems: These utilize chemical or physical means, such as chlorination or ultraviolet (UV) light, to kill remaining pathogens and harmful microorganisms.

Choosing the right water treatment equipment requires careful consideration of various factors, including equipment sizing, selection, and installation. Proper sizing ensures that the equipment can effectively treat water within the desired capacity, while appropriate selection considers factors like treatment method, efficiencies, and compatibility with the existing system. Finally, the installation of water treatment equipment must be done according to regulatory requirements and best practices, ensuring optimal operation and longevity.

Key Components of Wastewater Treatment Equipment

In this section, we will explore the crucial components of wastewater treatment equipment and their role in the four main treatment stages: preliminary, primary, secondary, and tertiary. It’s crucial to understand the importance of each component and their requirements for proper sizing, selection, and installation for efficient wastewater treatment. Preliminary treatment sets the stage for the removal of larger solids and impurities from wastewater. Key equipment used in this phase includes:

Screens: These devices remove larger objects and debris from the wastewater to prevent damage to downstream equipment.

Grit chambers: These systems separate and collect grit and sand particles from the wastewater stream, preventing abrasion and unnecessary wear on downstream equipment.

Sedimentation tanks: These tanks allow solids in the wastewater to settle, forming sludge that can be removed for further processing or disposal. In the secondary treatment stage, biological processes are utilized to break down organic matter in the wastewater. Key components here include:

Biological treatment systems: These systems use microorganisms to decompose organic pollutants in wastewater. Examples include activated sludge systems and trickling filters.

Secondary clarifiers: After the biological process, wastewater flows through secondary clarifiers to allow any remaining solids to settle. Tertiary treatment is the final stage where additional pollutants are removed, and the wastewater is disinfected. Some of the equipment used in this stage are:

Membrane filtration: These systems use ultrafiltration or reverse osmosis processes to remove fine particles, bacteria, and other contaminants.

Nutrient removal: Systems such as denitrification and phosphorus removal processes help to eliminate excess nutrients from the wastewater, preventing water eutrophication.

To ensure efficient operation of wastewater treatment equipment, it is essential to select the appropriate equipment size and type for each project, considering factors such as capacity, performance requirements, and space constraints. Additionally, proper installation by skilled professionals is of utmost importance to avoid malfunctions and ensure optimal performance. Understanding the key components of wastewater equipment and their roles in each treatment stage will enable construction specification experts to design the most effective and efficient wastewater treatment systems

Latest Technologies and Innovations in Water and Wastewater Equipment

The continuous evolution of technology has significantly impacted the water and wastewater treatment sectors. In this section, we will explore the latest technologies and innovations in water and wastewater equipment, highlighting how these advancements contribute to more efficient and sustainable treatment processes.

Intelligent Water Systems

One of the cutting-edge technologies revolutionizing the water and wastewater treatment sector is intelligent water systems. These systems employ advanced sensors, communication networks, and data analytics to enhance decision-making, automate processes, and optimize treatment operations. By integrating real-time monitoring, data analysis, and predictive modeling, intelligent water and wastewater systems allow construction specification experts to streamline operations, reduce energy consumption, and minimize maintenance costs.

Membrane Bioreactors (MBRs)

Membrane bioreactors (MBRs) have emerged as a highly efficient and innovative treatment solution, combining the biological treatment process with membrane filtration. MBRs offer several benefits, such as small footprint, enhanced nutrient removal, and high-quality effluent. This cutting-edge technology significantly improves the overall efficiency of wastewater treatment while reducing operational complexity and capital costs. Furthermore, the adoption of MBRs has paved the way for water reuse applications, promoting sustainable water management practices.

Ultraviolet (UV) Disinfection

Ultraviolet (UV) disinfection is a sustainable and chemical-free solution for water and wastewater treatment. This technology utilizes ultraviolet light to inactivate harmful microorganisms, ensuring pathogen-free, clean water. By avoiding the use of chemicals, UV disinfection mitigates the risk of harmful byproducts and benefits the environment. Moreover, the integration of UV disinfection as a final treatment step guarantees safe and reliable water quality standards.

Staying up-to-date with these advancements is crucial for construction specification experts to ensure that they are incorporating the most efficient and sustainable solutions in their projects. By adopting innovative technologies like intelligent water systems, membrane bioreactors, and ultraviolet disinfection, experts can effectively manage water and wastewater equipment, improve treatment efficiency, and promote sustainability in the construction industry.

Maintenance and Troubleshooting of Water and Wastewater Equipment

In this section, we will discuss the critical aspect of maintaining and troubleshooting water and wastewater equipment. Regular maintenance ensures optimal performance and extends equipment life, while effective troubleshooting helps identify and resolve issues that may arise during operation.

The Importance of Routine Maintenance

Routine maintenance checks should be scheduled as part of the overall management plan for water and wastewater equipment. These checks prevent equipment failure, save on expensive repairs, and ensure the longevity of the system. To help maintain peak performance, consider the following maintenance tasks:

Inspecting equipment for wear and tear: Regularly assess pumps, motors, valves, and other components for signs of wear, damage, or corrosion. Replace worn or damaged parts promptly to prevent further deterioration and costly downtime.

Cleaning filters and membranes: Over time, filters and membranes may become clogged, reducing the efficiency of the treatment process. Regular cleaning helps maintain the effectiveness of the filtration system and ensures the quality of treated water.

Ensuring proper operation of control systems: Control systems are vital for monitoring and regulating water and wastewater equipment. Make sure they function correctly and maintain accurate records of system performance data.

Addressing Common Issues through Troubleshooting

Despite regular maintenance, issues may arise with water and wastewater equipment. Here are some common problems and tips on how to troubleshoot them effectively:

Clogged filters: Check filters for debris, and clean or replace them as needed to restore proper water flow and treatment efficiency.

Pump malfunction: Inspect pumps for wear or damage, and ensure they are operating at the correct pressure and flow rate. Replace or repair defective pumps to avoid system failure.

Leaking pipes or valves: Examine pipes and valves for leaks or damage, and repair or replace them as necessary to minimize water loss and maintain treatment effectiveness.

Control system errors: Investigate any unusual readings or error messages from the control system. The issue could be a faulty sensor, wiring, or software glitch, and may require professional assistance to resolve.

Conclusion

Maintenance and troubleshooting play crucial roles in ensuring the optimal operation of water and wastewater equipment. By performing regular inspections, cleaning filters and membranes, and addressing common issues in a timely manner, construction specification experts can guarantee longevity, efficiency, and reliability in their water and wastewater systems. Keywords to include: maintenance, troubleshooting, water and wastewater equipment, routine checks, equipment inspection, wear and tear, filter cleaning, membrane cleaning, control systems, common issues.

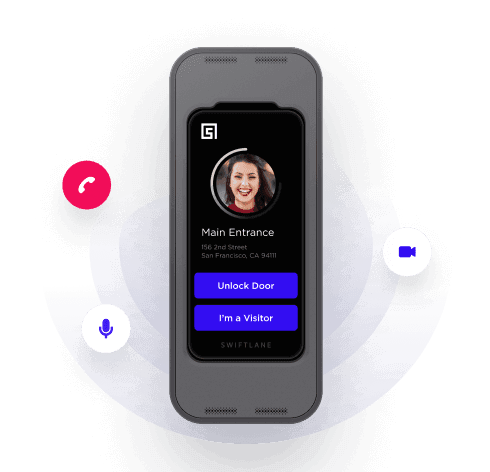

Upgrade Your Building Security

Get in touch with a Swiftlane specialist for more information on the best access control and video intercom solution for your building.