Welcome to the fascinating world of CSI Division 41, where material processing and handling equipment reigns supreme! In this comprehensive blog post, we’ll explore the ins and outs of Division 41, its various subcategories, best practices for selecting equipment, understanding industry standards, maintenance and safety considerations, and exciting future trends on the horizon. In any construction project, efficient, reliable, and safe material processing and handling equipment is essential. Whether you’re dealing with concrete, steel, wood, or other raw materials, you need top-notch equipment to transport and manipulate these elements as your project progresses. That’s where CSI Division 41 comes into play, so grab your hard hat and let’s dive in!

Suggested Posts:

An In-Depth Overview of CSI Division 05 – Metals

Master the Art of Utilities Construction with CSI Division 33

Introduction to CSI MasterFormat and Division 01

Introduction to CSI Division 41

In this informative guide, we will explore the significance CSI Division 41- Material Processing and Handling Equipment within the construction industry and provide an overview of its various subcategories. Material processing and handling equipment play a paramount role in construction projects by ensuring the smooth and efficient transportation, organization, and storage of materials, components, and waste. Their importance cannot be overstated, as they directly impact project timelines, budgets, and overall efficiency. MasterFormat, a universally recognized construction specification system, organizes its construction-related information into various divisions. Division 41 specifically deals with material processing and handling equipment and encompasses six main subcategories:

- 41 10 00 – Bulk Material Processing Equipment

- 41 20 00 – Piece Material Handling Equipment

- 41 30 00 – Manufacturing Equipment

- 41 40 00 – Container Processing and Packaging

- 41 50 00 – Material Storage

- 41 60 00 – Mobile Support Equipment

In the subsequent sections of this guide, we will dive deeper into these subcategories and provide insights into selecting, maintaining, and operating material processing and handling equipment within industry standards. Stay tuned as we unravel the complexities of CSI Division 41 and equip you with essential knowledge for your construction projects. Our aim is to enable you to make informed decisions, foster efficiency, and optimize your project budgets while mastering the art of Material Processing and Handling. In the next section, we will explore the subcategories of CSI Division 41 in detail, providing examples of equipment typically found in each subcategory and examining their applicability to various types of construction projects. See you there!

Exploring Subcategories of CSI Division 41

In this section, we will delve deeper into the various subcategories under CSI Division 41. Each subcategory holds specific relevance to material processing and handling in construction projects. Below, we will explore the subcategories 41 10 00, 41 20 00, 41 30 00, 41 40 00, 41 50 00, and 41 60 00.

41 10 00 – Bulk Material Processing Equipment

This subcategory includes equipment designed for the processing of bulk materials such as aggregates, sand, gravel, and crushed stone. Examples of equipment in this subcategory include crushers, screens, conveyors, and feeders. These devices aid in the production of construction materials, ensuring consistent quality, and meeting project requirements.

41 20 00 – Piece Material Handling Equipment

Piece Material Handling Equipment refers to equipment designed for the handling and movement of indivisible loads, such as equipment for lifting, stacking, and storing construction materials. Examples include forklifts, pallet jacks, hoists, and cranes. These devices help improve efficiency and productivity on a construction site while maintaining safety.

41 30 00 – Manufacturing Equipment

This subcategory includes equipment used in the manufacturing of construction materials or components. Examples include concrete mixers, brick and block making machines, and extruders for manufacturing PVC pipes. These devices enable the production of custom-made construction materials that meet specific project requirements.

41 40 00 – Container Processing and Packaging Equipment

Container Processing and Packaging Equipment includes devices used for filling, sealing, and packaging construction materials and products. Examples of equipment in this subcategory are bagging machines for cement, sealant dispensers, and adhesive applicators. This equipment ensures that construction materials are packed and sealed appropriately for transportation and storage.

41 50 00 – Material Storage Systems

Material Storage Systems refer to equipment designed for the storage and organization of construction materials, such as shelving, racks, and mezzanines. These storage solutions help maximize space utilization, enhance inventory control, and ensure quick access to essential materials on a construction site.

41 60 00 – Unassigned

This subcategory is currently unassigned, which means that it is reserved for future expansion or changes in the construction industry. By understanding the various subcategories within CSI Division 41, construction professionals can better select the right material processing and handling equipment for their specific projects. This knowledge not only ensures that project requirements are met but also helps in maximizing efficiency and minimizing costs. In the next section of this blog, we will discuss best practices for selecting Material Processing and Handling Equipment for construction projects.

Best Practices for Selecting Material Processing and Handling Equipment.

Selecting the right material processing and handling equipment is crucial in ensuring the smooth execution of any construction project. In this section, we will discuss the critical factors to consider while selecting the appropriate equipment and offer practical tips to help you make informed decisions to meet your project requirements and maximize efficiency while minimizing costs.

Factors to Consider when Selecting Equipment

Project Requirements: Before selecting any equipment, it’s essential to evaluate the project requirements and understand the specific needs, such as lifting capacity, material type, and processing or handling volume. This assessment will help you choose the appropriate equipment tailored for your project.

Budget: Set a realistic budget for Material Processing and Handling Equipment. The budget should include the purchasing or renting cost, operational costs, and maintenance expenses. Comparing the features of different equipment within your budget constraints will help in making a cost-effective decision.

Available Space: Examine the site’s available space, as the equipment size and maneuverability will directly impact efficiency. Choose equipment that can easily access and work within the site’s confined spaces.

Equipment Efficiency: Analyze the equipment’s performance and productivity in terms of cycle time, fuel consumption, and ease of operation. Higher efficiency will lead to increased project output and reduced operational costs.

Tips for Choosing the Right Equipment

Research: Explore multiple brands and models of Material Processing and Handling Equipment, and compare their features, price, and customer reviews to make an informed decision.

Consult Experts: Seek guidance from industry professionals or experienced colleagues who have used similar equipment in the past. Their insights can help you avoid potential pitfalls and select the right equipment for your project.

Consider Renting: If purchasing equipment is not a viable option, renting can provide access to modern, well-maintained machinery for the project’s duration.

Test the Equipment: Before making a final decision, conduct a field test to ensure the equipment performs efficiently in real-world conditions.

Consequences of Inadequate Equipment Selection

Inadequate equipment selection can lead to serious consequences, such as:

Project Delays: The wrong equipment may not adequately handle the project’s requirements, leading to delays and reduced productivity.

Increased Costs: Unsuitable equipment can cause inefficiencies, resulting in increased operational and maintenance costs.

Safety Hazards: Inappropriate equipment may pose safety risks to operators and other site workers, potentially leading to accidents and injuries.

In conclusion, making informed decisions while selecting Material Processing and Handling Equipment is vital for the successful completion of construction projects. Carefully considering factors such as project requirements, budget, available space, and equipment efficiency will help you choose the right equipment to meet your project goals effectively, while minimizing costs and ensuring worker safety.

Understanding Industry Standards and Regulations for Material Processing and Handling Equipment

Adhering to industry standards and regulations when it comes to material processing and handling equipment is very important. In this section, we will take a closer look at these essential guidelines, their purposes, and potential implications for your construction projects.

Introduction to Relevant Industry Standards and Regulations

Several organizations set standards and regulations for material processing and handling equipment, with the main ones being the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). These guidelines aim to ensure the safety and efficiency of equipment operation in construction projects. OSHA focuses on the safety and health aspect of equipment operation, setting regulations related to worker safety, hazard communication, and maintenance schedules. For instance, OSHA’s standard on Powered Industrial Trucks (29 CFR 1910.178) covers essential safety requirements for forklifts and other similar devices. ANSI establishes voluntary consensus standards for a wide range of industries, including construction. Notably, the ANSI/ASME B30.20 Standard covers the safety requirements for below-the-hook lifting devices. Additionally, ANSI/ITSDF B56.1 covers safety regulations for forklifts and other powered industrial trucks.

Impact of Regulations on Material Processing and Handling Equipment Selection and Use

The industry standards and regulations have a significant impact on the selection, installation, and use of Material Processing and Handling Equipment. When complying with these guidelines, you’ll be ensuring the safety and health of workers, minimizing equipment downtime, and reducing the risk of penalties or fines for non-compliance. To achieve compliance, make sure to:

- Choose equipment that meets or exceeds the industry standards established by OSHA, ANSI, and other relevant organizations.

- Properly install and maintain the equipment according to the manufacturer’s recommendations, and incorporate safety guidelines from regulatory agencies.

- Train your operators and workers on safe equipment operation, adhering to the best practices outlined by OSHA and ANSI.

Consequences of Non-Compliance with Industry Standards and Regulations

Ignoring industry standards and regulations can lead to severe consequences for your construction project. Potential risks include:

Workplace accidents and injuries: Non-compliance with safety guidelines puts workers at risk and may lead to severe injuries or fatalities.

Equipment breakdowns and project delays: Equipment malfunctioning due to poor maintenance practices can result in project delays and increased costs.

Fines and penalties: Regulatory agencies, like OSHA, may impose fines or other penalties on projects found in non-compliance with their guidelines.

Understanding and adhering to industry standards and regulations for material processing and handling equipment is a crucial aspect of any construction project. Compliance not only ensures worker safety and reduces the risk of equipment breakdowns but also helps you avoid fines and penalties that could derail your project’s success.

Maintenance and Safety Considerations for Material Processing and Handling Equipment

Maintaining material processing and handling equipment in optimal working condition is crucial for ensuring the success and safety of any construction project. In this section, we will discuss the importance of proper maintenance and safety practices, common maintenance tasks, and best practices for operating and handling equipment, to prevent accidents and injuries.

The Importance of Regular Maintenance

Regular maintenance of material processing and handling equipment is essential for several reasons:

Equipment Longevity: Well-maintained equipment lasts longer, reducing the need for frequent replacements and saving money in the long run.

Increased Efficiency: Regular maintenance ensures that equipment operates at peak efficiency, reducing energy consumption and lowering operating costs.

Prevention of Breakdowns: Performing maintenance tasks on a routine basis helps identify and resolve minor issues before they escalate into costly breakdowns.

Safety: Proper maintenance of equipment is crucial for ensuring worker safety and preventing accidents on the construction site.

Common Maintenance Tasks and Their Frequency

Some common maintenance tasks for material processing and handling equipment include:

Daily Inspections: Inspect equipment daily to identify any potential issues, such as leaks, loose bolts, or worn components. Address issues promptly to prevent accidents and breakdowns.

Lubrication: Regularly lubricate moving parts to reduce friction and wear, ensuring smooth operation and extending the equipment’s lifespan.

Cleaning and Debris Removal: Keep equipment clean and free of debris to prevent blockages and impairment of performance.

Component Replacement: Replace worn or damaged components as needed to maintain equipment functionality and prevent breakdowns. Maintenance tasks should be performed according to manufacturer recommendations, as frequency may vary depending on the specific equipment type and usage.

Safety Considerations and Best Practices

Operating material processing and handling equipment safely is crucial to preventing accidents and injuries on construction sites. Below are some best practices to follow:

Training: Ensure that all operators receive comprehensive training on the safe and correct use of the equipment.

Personal Protective Equipment (PPE): Require operators to wear appropriate PPE, such as safety goggles, gloves, and hard hats, while operating equipment.

Proper Signage: Display clear signage around the construction site to indicate the presence of Material Processing and Handling Equipment and any potential hazards.

Pre-Operational Checks: Conduct thorough inspections before using equipment to ensure that all safety features are in place and functioning correctly.

Follow Manufacturer Guidelines: Adhere to manufacturer guidelines for equipment use, maintenance, and safety precautions.

Proper maintenance and safety practices are essential to ensure the longevity, efficiency, and safe operation of material processing and handling equipment. By adhering to these guidelines, construction professionals can minimize equipment-related accidents and injuries, while optimizing the performance and lifespan of their equipment. Stay tuned for our final section, where we will discuss future trends in Material Processing and Handling Equipment and their potential impact on the construction industry.

Future Trends in Material Processing and Handling Equipment

As technology continues to advance, the construction industry is experiencing exciting developments in material processing and handling equipment. In this final section, we will explore some of the future trends in this field and discuss their potential impact on construction projects.

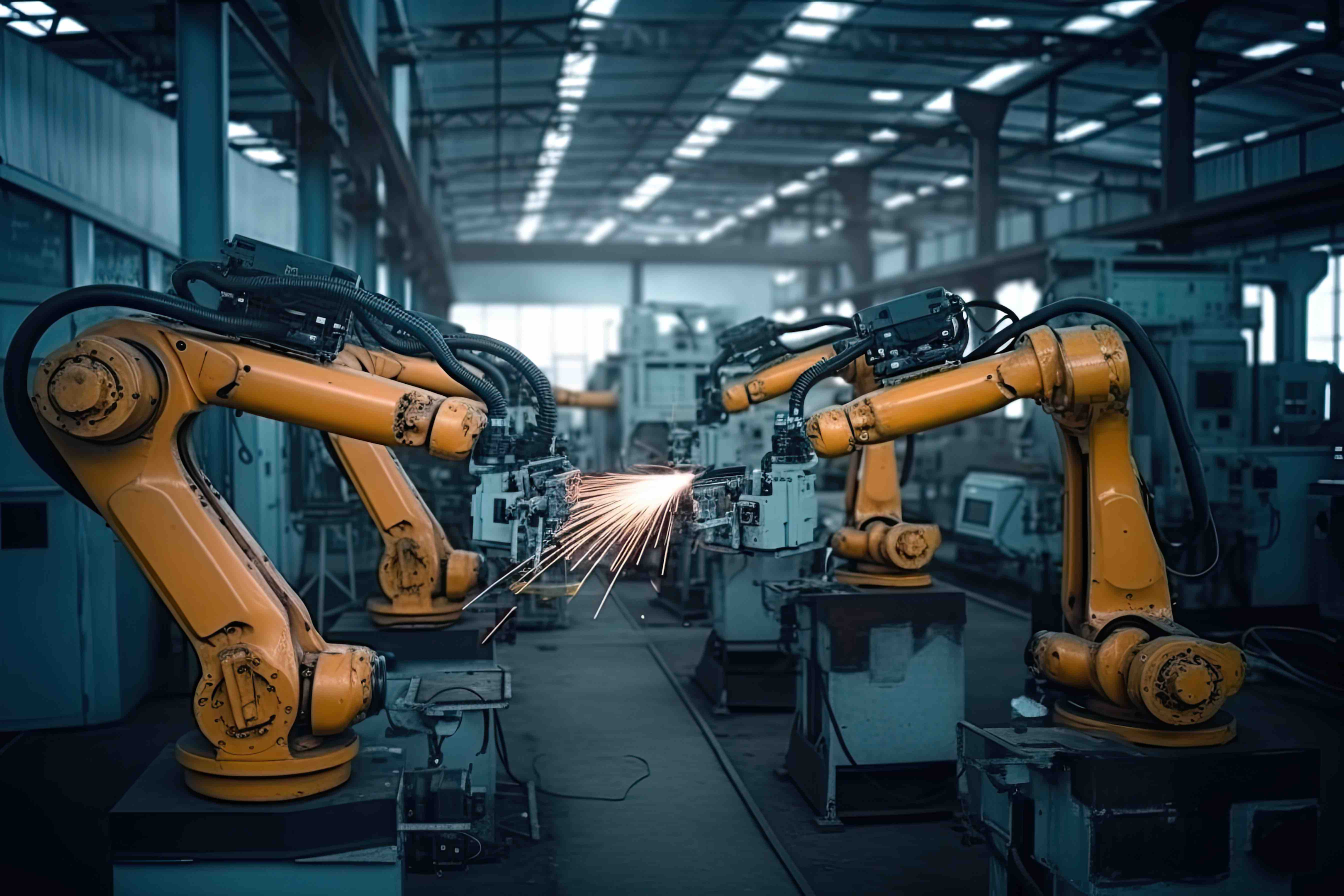

Automation and Robotics: Automation and robotics are transforming the way material processing and handling tasks are performed. Autonomous vehicles, robotic arms, and automated conveyor systems are being integrated into construction sites, increasing efficiency, precision, and safety. These technologies reduce the need for manual labor, streamline operations, and enhance overall productivity.

Internet of Things (IoT): The Internet of Things is making its mark on material processing and handling equipment. Connected sensors and devices gather real-time data on equipment performance, allowing for predictive maintenance, optimized workflows, and improved decision-making. IoT-enabled equipment provides valuable insights into usage patterns, energy consumption, and potential issues, enabling proactive maintenance and resource management.

Artificial Intelligence (AI): AI-powered technologies are revolutionizing material processing and handling equipment. Machine learning algorithms analyze vast amounts of data, optimizing equipment performance, and identifying patterns for predictive maintenance. AI can also enhance safety by detecting potential hazards, alerting operators, and even autonomously responding to emergency situations.

Conclusion

CSI Division 41 – Material Processing and Handling Equipment plays a critical role in the construction industry, ensuring the efficient transportation, organization, and storage of materials. By understanding the various equipment subcategories within Division 41, construction professionals can select the appropriate equipment for their projects, enhancing efficiency and minimizing costs.

Selecting the right equipment involves considering project requirements, budget constraints, available space, and equipment efficiency. Adhering to industry standards and regulations is crucial for ensuring the safety and compliance of Material Processing and Handling Equipment.

Proper maintenance and safety practices are essential for the longevity, efficiency, and safe operation of equipment. Regular inspections, lubrication, cleaning, and component replacement are key maintenance tasks. Following safety guidelines, providing comprehensive training, and using appropriate personal protective equipment are essential for accident prevention.

Looking to the future, we anticipate significant advancements in Material Processing and Handling Equipment, driven by automation, IoT, AI, sustainability, enhanced safety features, and modular designs. Embracing these trends will enable construction and material processing professionals to leverage cutting-edge technologies, improve productivity, and meet the evolving needs of the industry.

We hope this comprehensive guide on CSI Division 41 – Material Processing and Handling Equipment has provided you with valuable insights and practical knowledge. By staying informed about the latest developments and best practices, you can elevate your construction projects to new heights of efficiency, safety, and success.

Upgrade Your Building Security

Get in touch with a Swiftlane specialist for more information on the best access control and video intercom solution for your building.