Welcome to the comprehensive guide on CSI Division 05 – Metals, where we will delve into the importance and relevance of metals in the construction industry.

Metals play a vital role in various aspects of construction projects, and the right selection and use of these materials can significantly impact the success of your project. In this all-encompassing guide, we will explore the different types of metals, their advantages and drawbacks, and the factors to consider when working with them. We will also share insights on the proper selection, specification, fabrication, and installation techniques of metals, as well as discuss future trends and innovations in this sector. So, buckle up, and let’s embark on this journey to optimize your construction project with metals.

Suggested Posts:

Introduction to CSI MasterFormat and Division 01

Getting to Grips with CSI Division 02 – Existing Conditions in Construction Projects

Mastering Division 09 – Finishes in the CSI MasterFormat System for Improved Project Success

Understanding CSI MasterFormat: Division 14- Conveying Equipment

Master the Art of Utilities Construction with CSI Division 33

Division 48 – A Comprehensive Guide to Electrical Power Generation in Construction

Why Metals Matter in the Construction Industry

Metals have been an integral part of the construction industry for centuries, offering numerous benefits such as strength, durability, and versatility. They are widely used as structural, architectural, and engineering elements, catering to diverse requirements and project specifications.

By understanding the various metals available and their unique properties, a construction specification expert can efficiently select the most suitable materials for a specific project, ultimately enhancing its quality, longevity, and aesthetic appeal. Given the significance and prevalence of metals, it is essential to remain up-to-date with the latest trends, techniques, and best practices in the field.

The Key Concepts You’ll Learn in This Guide

This comprehensive guide will cover several essential aspects of CSI Division 05, including:

- Understanding the different types of metals and their applications

- Proper selection and specification of metals

- Metal fabrication and installation techniques

- A step-by-step guide to managing metals in construction projects

- Addressing common challenges and issues in working with metals

Understanding the Different Types of Metals and Their Applications

In construction projects, metals play a crucial role in providing both structural integrity and aesthetic appeal. To create a successful project that satisfies all requirements, it is essential to familiarize oneself with the various types of metals, their properties, and their applications. This knowledge will allow construction specification experts to optimize project outcomes and better manage CSI Division 05 requirements. This section will delve into the different types of metals used in construction, starting with structural metals.

Structural Metals

Structural metals, such as steel, aluminum, and iron, are the backbone of many construction projects. These metals are characterized by their strength, rigidity, and durability, making them ideal for load-bearing applications.

- Steel: As one of the most commonly used structural metals, steel offers excellent strength-to-weight ratio, ductility, and corrosion resistance. In construction projects, steel is often used for columns, beams, and reinforcement bars (rebars). When coated with zinc, steel exhibits even more excellent resistance to corrosion, making it ideal for use in various environments.

- Aluminum: Another popular metal in the construction industry, aluminum is lightweight, corrosion-resistant, and easily formable, making it suitable for various applications such as window frames, doors, and cladding.

- Iron: Despite its susceptibility to corrosion, iron still finds its place in construction, particularly in the form of cast iron. Cast iron is known for its ability to withstand heavy loads and its resistance to wear, making it suitable for applications like pipes and column supports.

Architectural Metals

Architectural metals focus primarily on the visual aspects of a construction project, encompassing metals like copper, brass, bronze, stainless steel, and zinc. These metals’ attractive appearance and various finishes make them ideal for decorative features such as facades, panels, and ornaments.

- Copper: With its natural reddish-brown hue, copper is often used for roofing, cladding, and ornamental details. When exposed to the elements, copper develops a green patina that serves as a protective layer against further corrosion.

- Brass: This alloy of copper and zinc presents a unique gold-like appearance, making it suitable for decorative fixtures and fittings such as door handles and light fixtures.

- Bronze: An alloy of copper and tin, bronze is another aesthetically pleasing metal used for statues, plaques, and architectural accents.

Engineering Metals

Engineering metals are primarily used for specialized construction applications due to their unique properties. Examples of these metals include titanium, tungsten, and nickel alloys.

- Titanium: With its high strength-to-weight ratio and excellent corrosion resistance, titanium is often used in demanding applications such as structures in marine environments or bridges exposed to harsh weather conditions.

- Tungsten: Known for its high melting point and resistance to wear, tungsten is often used as a component in steel and other alloys to improve their properties.

- Nickel Alloys: These metals exhibit excellent resistance to corrosion and heat, making them suitable for use in chemical processing plants and other specialized construction projects.

By understanding the different types of metals and their applications in construction projects, construction specification experts can make informed decisions when selecting and specifying materials, optimizing project outcomes, and leveraging the potential of CSI Division 05 – Metals.

Proper Selection and Specification of Metals

In this section, we will discuss the factors to consider when selecting a metal and the importance of accurate specifications and documentation to ensure the best outcome for your construction project.

Evaluating Structural and Aesthetic Properties

Every metal has its unique properties, such as strength, ductility, corrosion resistance, and aesthetics. To optimize the metal selection process, consider the structural requirements of the project – does it need to support heavy loads, or resist harsh environmental conditions? Likewise, consider the visual appeal you want to achieve – should it be sleek and modern or have a traditional, rustic look? Evaluating the overall design and engineering requirements will guide you in finding the ideal metal for your project.

Balancing Cost and Performance

Another crucial factor when selecting a metal is the balance between cost and performance. While some metals, such as stainless steel or aluminum, can offer superior performance and durability, they also come at a higher price. Assess the project’s budget, long-term maintenance costs, and the desired lifespan of the structure before making a decision. Remember, a lower upfront cost might not always translate to long-term savings if the material degrades quickly or requires frequent maintenance.

Considering Environmental Factors

Specification of metals should also take into account the environmental factors specific to the project site. For example, metals exposed to marine environments or chemical substances require higher corrosion resistance. Similarly, metals located in areas prone to seismic activity or high wind loads should have sufficient ductility and fatigue resistance. Understanding these environmental factors will help you select a metal that not only meets the project’s requirements but also contributes to its sustainability and longevity.

The Importance of Accurate Specifications and Documentation

To achieve the best results for your construction project, it’s essential to provide accurate specifications and documentation. This includes details on the type of metal, dimensions, finishes, and any special requirements such as fabrication or installation methods. Providing clear, concise information will enable fabricators and contractors to understand the project’s objectives and ensure consistency throughout the construction process.

In summary, proper metal selection and specification require a thorough understanding of the project’s structural, aesthetic, and environmental requirements. By carefully considering these factors and providing accurate documentation, you can optimize your project’s performance, durability, and visual appeal. Remember to incorporate SEO keywords such as “metal selection”, “specification of metals”, and “construction project” throughout your content for increased online visibility and engagement.

Metal Fabrication and Installation Techniques

In this section, we will explore various metal fabrication and installation techniques commonly employed in the construction industry. By understanding these methods, construction specification experts can ensure that their projects achieve durability, performance, and visual appeal. Our discussion will focus on four major fabrication and installation techniques: welding, bolting, riveting, and adhesive bonding.

Welding

Welding is a popular metal fabrication technique that involves the joining of two metal pieces by melting and fusing their surfaces. This process requires a high level of skill and expertise to ensure strong and durable bonds. There are several types of welding processes, including arc welding, gas welding, and resistance welding, each with its unique applications and advantages. While welding provides robust bond strength and a seamless appearance, it may also require additional resources and safety precautions.

Bolting

Bolting is a straightforward installation technique that joins metal components by utilizing mechanical fasteners like bolts, nuts, and washers. This method is widely used in structural applications, such as in steel framing and support systems. Bolting offers quick and cost-effective installation, easy disassembly, and reduced maintenance requirements. However, it may be less suitable for certain aesthetic applications, as the fasteners may be visible.

Riveting

Riveting, a traditional metal joining technique, involves the use of a malleable metal pin or rivet to connect two metal components securely. This method has been employed in construction projects for centuries and remains popular due to its proven reliability and high load-bearing capacity. Riveting is particularly suited for applications where high shear and torsional stresses are expected. However, it may be more labor-intensive and time-consuming than other installation techniques.

Adhesive Bonding

Adhesive bonding is an alternative method for joining metals that utilizes chemical adhesives to create a secure bond between metal surfaces. This technique is gaining popularity for its aesthetically pleasing results, as no fasteners or weld marks are visible. Additionally, adhesive bonding can accommodate complex shapes and materials, including dissimilar metals and composite materials. However, proper surface preparation and adhesive selection are critical to ensuring a strong and durable bond.

By understanding and properly implementing these metal fabrication and installation techniques, construction specification experts can optimize the performance, durability, and appearance of their projects. As the industry continues to evolve, it is essential for professionals to stay informed of the latest advancements and best practices in metal fabrication and installation. By doing so, they can manage their projects effectively and maintain a competitive edge in the ever-changing construction landscape.

A Step-By-Step Guide to Managing Metals in Construction Projects

In this section, we will explore a detailed step-by-step guide to managing metals in construction projects, providing practical tips and considerations to help construction specification experts optimize their workflow. From material selection to specification, fabrication, installation, maintenance, and eventual replacement, this guide covers every aspect of metals management in construction.

Step 1: Material Selection and Specification

The first step in managing metals in a construction project is selecting the appropriate material based on factors such as structural and aesthetic properties, cost, and environmental impact. Researching and understanding the properties of various metals are crucial for making informed decisions.

Step 2: Procurement and Documentation

Once the appropriate metal has been selected, it’s essential to procure the materials and ensure proper documentation is in place. This includes detailed specifications, material data sheets, quality control guidelines, and any other relevant information to ensure compliance with industry standards and regulations.

Step 3: Fabrication and Installation Techniques

Next, consider the most effective fabrication and installation techniques for the specific metal and project requirements. Common techniques include welding, bolting, riveting, and adhesive bonding. Familiarize yourself with these methods and choose the most suitable approach for your project.

Step 4: Quality Control and Assessment

Implementing a robust quality control and assessment plan is crucial to ensure the durability, performance, and visual appeal of the metal components in your project. Regular inspections, testing, and evaluations should be conducted to identify and address any issues or inconsistencies that may arise during the fabrication and installation process.

Step 5: Maintenance and Protection

Proper maintenance and protection of metal components are essential to prolong their lifespan and maintain their structural integrity. This may involve regular cleaning, inspection, and application of protective coatings to prevent corrosion, wear, and other forms of degradation.

Step 6: Replacement and Recycling

Finally, it’s important to plan for the eventual replacement of metal components at the end of their service life. This may involve selecting metals with a long lifespan, incorporating modular or easily replaceable components, and considering recycling options to minimize waste and environmental impact.

In conclusion, managing metals in construction projects is a multi-faceted process that requires careful planning, expertise, and ongoing vigilance. By following this step-by-step guide construction specification experts can ensure the successful integration of metals in their projects, optimizing performance, aesthetics, and longevity.

Addressing Common Challenges and Issues in Working with Metals

When working with metals in construction projects, construction specification experts often encounter various challenges and issues. In this section, we will discuss some of the most common problems, including corrosion, thermal expansion, and material inconsistencies, and provide practical solutions to overcome these challenges. By understanding these issues and knowing how to address them, you can ensure the success of your projects while maintaining structural integrity and aesthetic appeal.

Corrosion: Prevention and Control

Corrosion is a significant concern in metal construction as it leads to the deterioration of metal structures, causing potential safety hazards and costly repairs. Some preventative measures to avoid corrosion include:

- Material Selection: Choose metals with inherent corrosion resistance, such as stainless steel or aluminum.

- Protective Coatings: Apply coatings, like paint, galvanization, or other specialized coatings, to protect the metal from direct exposure to corrosive environments.

- Routine Maintenance: Perform regular inspections and maintenance to detect early signs of corrosion and take corrective action.

Thermal Expansion: Accommodating for Movement

Thermal expansion occurs when metals expand or contract due to temperature changes. This phenomenon can cause stress in the structure and lead to failure if not accounted for during the design and specification process. To address thermal expansion, consider the following:

- Expansion Joints: Incorporate expansion joints into your design to accommodate movement and prevent structural damage.

- Flexible Connections: Use flexible connections, e.g., rubber gaskets or bellows, to absorb movement between components.

- Thermal Insulation: Install insulation to minimize temperature fluctuations and reduce the impact of thermal expansion.

Material Inconsistencies: Ensuring Quality and Performance

Material inconsistencies can compromise the performance and durability of metal structures, leading to potential failures and costly repairs. To minimize material inconsistencies, implement the following strategies:

- Supplier Evaluation: Select reputable suppliers with a proven track record of providing high-quality materials.

- Material Testing: Perform quality control tests, such as tensile testing, hardness testing, or chemical analysis, to verify material properties and ensure consistency.

- Proper Fabrication Techniques: Use appropriate welding, cutting, and forming methods to maintain material properties and prevent defects during fabrication.

In conclusion, addressing common challenges and issues in working with metals is vital for construction specification experts to optimize the performance, durability, and visual appeal of metal structures. By incorporating preventative measures for corrosion, accommodating for thermal expansion, and ensuring material consistency, you can successfully navigate these challenges and contribute to a successful construction project.

Conclusion

In conclusion, the world of CSI Division 05 – Metals, and its expansive role in the construction industry is truly intriguing. Metals, serving as structural, architectural, and engineering components, are the very backbone of any construction project. By understanding the unique characteristics of different types of metals, construction specification experts can optimize the material selection, fabrication, installation, and maintenance processes, ultimately enhancing a project’s durability, aesthetic appeal, and longevity.

It’s crucial to stay abreast of current trends, future innovations, and best practices to continue reaping the benefits of metals in construction. By strategically selecting, specifying, fabricating, installing, and managing metals in line with project specifications and environmental conditions, we can push the boundaries of architectural and engineering feats. The key to unlocking the true potential of metals in construction lies in knowledge, careful planning, and meticulous execution. From structural metals to architectural ones, right through to engineering metals, this guide serves as a stepping stone towards mastering the realm of CSI Division 05 – Metals.

Have Questions?

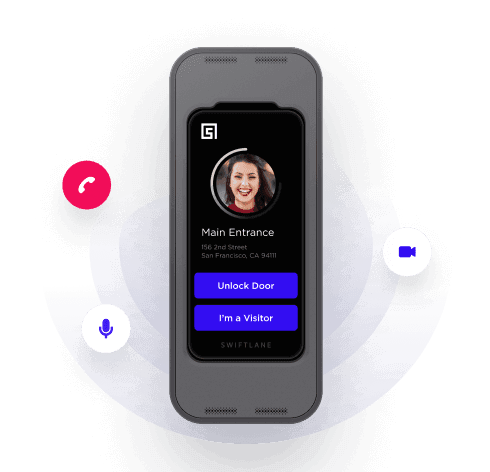

Get in touch with our team to learn more about what Swiftlane can do for you.