Welcome to this comprehensive guide on pollution control equipment in the construction industry. In today’s world, it is more important than ever to prioritize sustainable and eco-friendly practices in every sector, including the construction industry.

In this blog post, we will delve into the various types of pollution control equipment, their importance in construction projects, and best practices for their implementation. Using pollution control equipment is vital for mitigating the environmental impacts of construction projects. These measures not only help in protecting our environment but also ensure the health and safety of construction workers and the surrounding community.

Some of the critical issues addressed by pollution control equipment in the construction industry include air pollution, water pollution, noise pollution, and waste management. By incorporating these technologies, construction professionals can work towards achieving sustainable construction practices that contribute to an overall cleaner and healthier environment. Throughout the blog post, we will discuss various pollution control equipment and their applications in construction projects. These include:

- Air Pollution Control Equipment

- Water Pollution Control Equipment

- Noise and Vibration Control Equipment

- Waste Management and Recycling Equipment

We will also emphasize the roles and responsibilities of project managers, contractors, and other stakeholders in ensuring the effective implementation of pollution control equipment, adherence to industry standards and regulations, and ultimately promoting sustainable construction practices. So, let’s dive into this essential topic and explore how the construction industry can contribute to a greener future by embracing pollution control equipment in their projects. Stay tuned for an informative and engaging discussion on this critical aspect of modern construction practices.

Suggested Posts:

Introduction to CSI MasterFormat and Division 01

Getting to Grips with CSI Division 02 – Existing Conditions in Construction Projects

Mastering Division 09 – Finishes in the CSI MasterFormat System for Improved Project Success

Understanding CSI MasterFormat: Division 14- Conveying Equipment

Master the Art of Utilities Construction with CSI Division 33

Division 48 – A Comprehensive Guide to Electrical Power Generation in Construction

Introduction to CSI Division 44 – Pollution Control Equipment

Incorporating pollution control equipment in construction projects not only helps in mitigating these environmental effects but also aids in achieving sustainability and maintaining compliance with industry standards. The primary goals of incorporating pollution control equipment in construction projects include:

- Minimizing air, water, noise, and solid waste pollution.

- Ensuring compliance with local, national, and international regulations.

- Enhancing the overall project sustainability.

- Maintaining a safe and healthy environment for workers and surrounding communities.

There are numerous types of pollution control equipment available for various construction activities. These can be broadly categorized into:

- Air Pollution Control Equipment

- Water Pollution Control Equipment

- Noise and Vibration Control Equipment

- Waste Management and Recycling Equipment

Adherence to industry standards and regulations is crucial in ensuring the effectiveness of pollution control equipment. Compliance not only protects the environment but also safeguards the interests of all stakeholders, including project owners, contractors, workers, and communities. Stay tuned for the following sections, where we will dive deeper into the specifics of the various types of pollution control equipment.

We will discuss the primary sources of pollution, the technologies and methods employed in controlling these pollutants, and the best practices for implementing this equipment in your construction projects. By the end of this blog post, you’ll have a solid understanding of the importance of pollution control equipment in construction projects and be armed with the knowledge to implement them effectively in your own projects.

Air Pollution Control Equipment

In this section, we’ll discuss the various types of air pollution control equipment used in construction projects. The construction industry is a significant contributor to air pollution, which can have detrimental effects on human health and the environment. By understanding the main types of air pollution generated in construction projects, such as particulate matter, volatile organic compounds (VOCs), and nitrogen oxides (NOx), you can select the most appropriate equipment to mitigate these emissions.

Particulate Matter

Particulate matter, or dust, is a common air pollutant in construction projects, especially during excavation, demolition, and material handling activities. To reduce dust emissions, consider the following air pollution control equipment:

- Wet Scrubbers: These devices use a liquid solution to remove dust and particles from the air. The wet scrubber solution traps the dust and then is either discharged or recycled for reuse.

- Fog and Mist Cannons: These devices release a fine mist of water into the air to capture and settle dust particles, minimizing dust emissions.

Volatile Organic Compounds

VOCs are harmful compounds that evaporate into the air from various construction materials, such as paint, solvents, and adhesives. VOC emissions can be controlled using the following equipment:

- Activated Carbon Filters: These filters adsorb VOCs from the air, trapping them within the filter material. Once the filter has reached its capacity, it must be replaced or regenerated.

- Thermal Oxidizers: This technology uses high temperatures to break down VOCs into less harmful compounds, reducing the overall VOC emissions.

Nitrogen Oxides

Nitrogen oxides, or NOx, are emitted primarily from the combustion of fossil fuels, such as diesel fuel used in construction equipment. Some air pollution control equipment for reducing NOx emissions include:

- Selective Catalytic Reduction (SCR) Systems: SCR systems use a catalyst and a reducing agent to convert NOx emissions into harmless nitrogen and water.

- Exhaust Gas Recirculation (EGR) Systems: EGR technology recirculates a portion of an engine’s exhaust gas back into the combustion chamber, reducing NOx emissions by lowering combustion temperatures.

By incorporating the appropriate air pollution control equipment in your construction projects, you can help protect the environment and adhere to industry standards and regulations. In the next section, we’ll explore the various types of water pollution control equipment used in construction projects.

Water Pollution Control Equipment

Water pollution control is an essential aspect of environmentally responsible construction projects. In this section, we will discuss the importance of controlling water pollution in construction projects, identify common sources of water pollution, and explore various water pollution control methods and equipment.

Importance of Controlling Water Pollution in Construction Projects

The construction industry has a significant impact on global water resources. Uncontrolled water pollution from construction sites can lead to damage to aquatic ecosystems, deterioration of water quality, and increased risks to human health. As a result, regulation and oversight of water pollution are critical for sustainable construction practices.

Common Sources of Water Pollution in Construction Projects

Three primary sources of water pollution in construction projects are sedimentation, chemical runoff, and construction debris.

- Sedimentation: Construction activities often involve soil excavation, resulting in the generation of sediment-laden water. The discharge of sediments into water bodies can cause harm to aquatic life, reduce water quality, and increase downstream flooding risks.

- Chemical Runoff: Construction projects use various chemicals, such as oils, solvents, and concrete additives, that can be carried away by rainwater or groundwater, contaminating nearby water sources.

- Construction Debris: Debris from demolition or construction activities, such as concrete, wood, and metals, can enter water sources, causing pollution and posing hazards to aquatic life.

Water Pollution Control Methods and Equipment

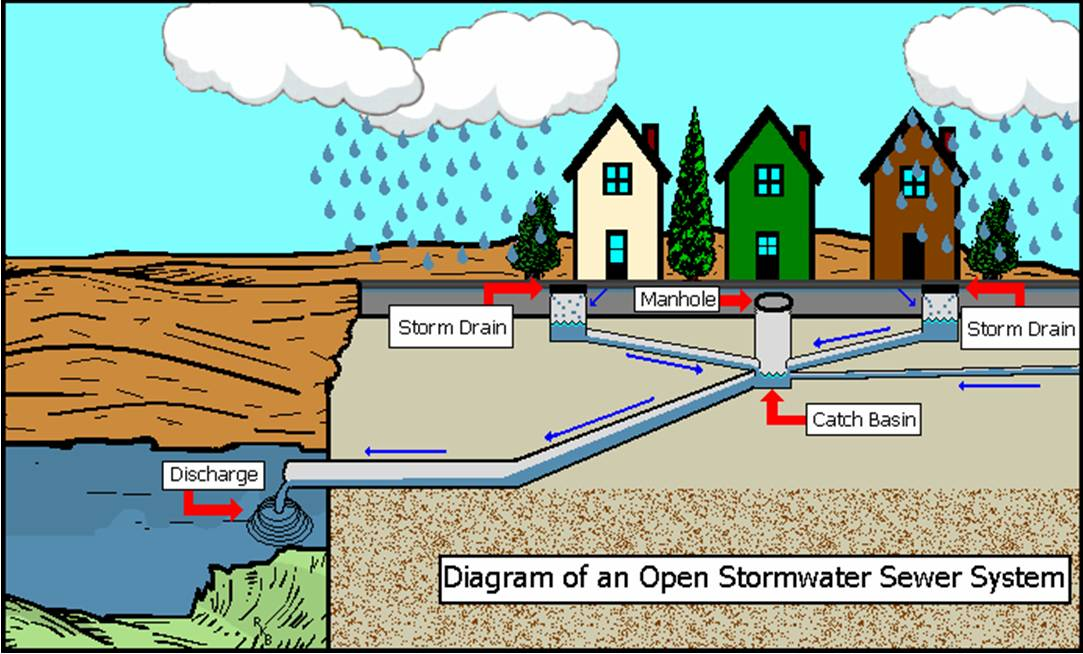

Several methods and equipment can be used to control water pollution in construction projects. Some of the most common water pollution control equipment includes sedimentation basins, silt fences, and stormwater management systems.

- Sedimentation Basins: Sedimentation basins, also known as sediment ponds or retention ponds, are large excavated areas designed to store and treat sediment-laden water. As the water sits in the basin, sediment particles settle to the bottom, allowing cleaner water to be discharged.

- Silt Fences: Silt fences are temporary barriers made from geotextile fabric that trap sediment and prevent it from entering water sources. Installed along the perimeter of construction areas, silt fences help reduce sediment-laden runoff from construction sites.

- Stormwater Management Systems: Stormwater management systems, such as detention ponds, infiltration trenches, and vegetative filter strips, help control the flow of stormwater runoff and minimize pollutants from entering water bodies.

To effectively control water pollution in construction projects, it is crucial to develop and implement a comprehensive Stormwater Pollution Prevention Plan (SWPPP) tailored to the specific needs and conditions of the project. This includes selecting appropriate technologies and equipment, regularly inspecting and maintaining control measures, and training personnel to manage potential pollution sources. By incorporating water pollution control equipment into construction projects, builders can minimize environmental impacts, comply with regulations, and contribute to sustainable development. In the next section, we will discuss noise and vibration control equipment, another crucial aspect of pollution control in construction projects.

Noise and Vibration Control Equipment

In this section, we will discuss the importance of noise and vibration control equipment in managing noise pollution within construction projects. While reducing the environmental impact of construction activities, it is crucial to consider the effects of noise and vibrations generated from construction sites, as they can negatively affect nearby residents and the surrounding ecosystem.

Sources of Noise Pollution in Construction Projects

Noise pollution is primarily caused by the operation of heavy machinery such as excavators, bulldozers, and pile drivers. Other activities like blasting and demolition also contribute to high noise levels, leading to disturbances for the people residing or working near the project site.

Noise and Vibration Control Equipment

To mitigate noise pollution, various strategies and equipment are used in construction projects. Here are some of the most common ones:

1. Noise Barriers

These are structures made of materials like wood, metal, or concrete, designed to absorb or deflect sound waves. Noise barriers are installed around the perimeters of a construction site, limiting the sound’s propagation to the surrounding area.

2. Acoustic Enclosures

These are soundproofed structures designed to contain and reduce the noise generated by a specific source, such as a generator or an air compressor. Acoustic enclosures can be custom-made or purchased pre-fabricated to fit the specific equipment in use.

3. Vibration Isolators

Vibration isolators are devices placed beneath noisy equipment to absorb vibrations and reduce the transmission of noise to the ground or other surfaces. These isolators are typically made of rubber, foam, or other materials with damping properties.

Best Practices for Implementing Noise and Vibration Control Equipment

- Assessing the noise levels: Before implementing any noise control measures, it is vital to conduct a noise assessment to determine the project’s noise levels and identify the primary noise sources.

- Selecting appropriate control equipment: Based on the noise assessment, select the most suitable noise and vibration control equipment for your project while considering the performance, cost-effectiveness, and durability of the equipment.

- Training and communication: Ensure that the site personnel, contractors, and other stakeholders are aware of the importance of noise control and understand the proper use and maintenance of the control equipment.

- Monitoring and evaluation: Regularly monitor the noise levels throughout the project duration and evaluate the effectiveness of the implemented noise and vibration control measures. Modify or adapt the strategies as necessary to maintain compliance with noise regulations and industry standards.

By effectively incorporating noise and vibration control equipment within construction projects, contractors and project managers can help create more sustainable and community-friendly construction environments that not only benefit the environment but also ensure the well-being of the people living and working in close proximity to the construction sites.

Waste Management and Recycling Equipment

Waste management and recycling have become increasingly critical in the construction industry due to the increasing awareness of the potential environmental impacts of improper waste disposal. In this section, we will explore various waste management and recycling equipment commonly utilized in construction projects, helping companies bolster their sustainability efforts while adhering to industry regulations.

Importance of Waste Management and Recycling Practices in Construction

Construction projects generate significant amounts of waste, including excess materials, packaging, and debris. Proper waste management and recycling practices are vital in preventing pollution and reducing the environmental impacts of construction activities. These practices not only help conserve natural resources and reduce landfill waste, but they also promote cost savings through material reuse and recycling.

Types of Waste Generated and Environmental Impacts

Waste generated in construction projects can be classified into various categories, such as:

- Inert waste: Bricks, concrete, and soil

- Non-hazardous waste: Packaging materials, wood, and metal

- Hazardous waste: Paints, solvents, and asbestos

Improper disposal of these wastes can negatively impact the environment by contaminating soil, water, and air, contributing to various environmental problems such as climate change, loss of biodiversity, and pollution.

Waste Management and Recycling Equipment

To mitigate these potential environmental impacts, several waste management and recycling equipment options are available for construction projects:

- Compactors: Compactors reduce the volume of waste materials through compression, making them easier to transport and dispose of in landfills. They come in various types, such as drum compactors for compacting large volumes of waste and portable compactors for on-site waste reduction.

- Balers: Balers are used to compress recyclable materials, such as cardboard, plastics, and metals, into compact bales for easy handling and transportation to recycling facilities.

- Recycling Containers: These containers help separate and collect different types of waste materials, such as paper, glass, and metals, for easy transportation to recycling centers.

By incorporating waste management and recycling equipment into construction projects, companies can effectively reduce their environmental footprint, adhere to industry standards, and contribute to overall sustainability in the construction industry.

In conclusion, proper waste management and recycling practices are crucial for the construction industry’s long-term environmental success. By understanding the types of waste generated and utilizing suitable equipment like compactors, balers, and recycling containers, construction projects can mitigate their environmental impact and support sustainable construction practices.

Have Questions?

Get in touch with our team to learn more about what Swiftlane can do for you.