Welcome to this comprehensive guide on CSI Division 04 – Masonry, where we dive deep into the fascinating world of masonry construction! We will provide you with valuable insights on the ins and outs of this age-old craft that has shaped countless magnificent structures worldwide. Our goal is to help you understand the key aspects of masonry, its applications in contemporary construction, and what the future holds for this essential component of our built environment.

So, go ahead and immerse yourself in this expertly-crafted guide and discover the secrets of this timeless construction method, hone your skills, and stay ahead of the curve as you conquer the world of building with brick, stone, and mortar. Let’s get started!

Suggested Posts:

Introduction to CSI MasterFormat and Division 01

Getting to Grips with CSI Division 02 – Existing Conditions in Construction Projects

Mastering Division 09 – Finishes in the CSI MasterFormat System for Improved Project Success

Understanding CSI MasterFormat: Division 14- Conveying Equipment

Master the Art of Utilities Construction with CSI Division 33

Division 48 – A Comprehensive Guide to Electrical Power Generation in Construction

Introduction to CSI Division 04 – Masonry

Welcome to our comprehensive guide on the CSI Division 04 – Masonry. From ancient structures to modern skyscrapers, masonry has been an essential component in building strong, durable, and visually stunning edifices for centuries. In this blog, we aim to take you through an in-depth exploration of the world of masonry in contemporary construction. We will be covering 5 distinct sections in this blog post:

- Masonry Materials and Their Properties

- Techniques and Best Practices in Masonry Construction

- Masonry Reinforcement, Joints, and Connectors

- Masonry Performance, Maintenance, and Sustainability

- Industry Trends, Innovations, and Future of Masonry

In the upcoming sections, we will discuss various aspects of masonry in detail, including the materials used, construction techniques, reinforcement methods, performance factors, sustainability practices, and the latest industry trends.

Our goal is to provide you with valuable insights and expert advice, helping you make informed decisions when specifying masonry work for your construction projects. So, without further ado, let’s dive into the fascinating world of masonry and explore everything it has to offer!

Masonry Materials and Their Properties

The world of masonry is rich in variety, with a wide array of materials accessible to construction professionals. In this section, we’ll take a closer look at these materials, their properties, potential applications, and the benefits they offer to various construction projects.

Bricks

Bricks come in various materials such as clay, concrete, and even glass. The most common type of brick, clay brick, offers excellent durability, fire resistance, and thermal insulation. Concrete bricks are known for their strength and versatility, while glass bricks provide unique aesthetic appeal and increased light transmission.

Blocks

Concrete blocks, also known as concrete masonry units (CMUs), are another popular choice among construction professionals. They are available in various sizes, shapes, and densities, providing options for both structural and decorative applications. Lightweight autoclaved aerated concrete (AAC) blocks are another option, known for their excellent insulation performance and easy workability.

Natural and Manufactured Stone

Natural stones, such as limestone, sandstone, granite, and marble, are often used in masonry work, providing timeless beauty and unparalleled durability. Meanwhile, manufactured stone veneer products emulate the appearance of natural stone while offering advantages such as lower cost and lighter weight.

Mortar

Mortar is used to bind masonry units together and is typically made from a mixture of sand, cement, water, and lime. Various types of mortar, such as Type N, S, M, and O, have distinct properties and applications, depending on factors such as compressive strength, bond strength, and water retention.

When selecting masonry materials, considerations such as climate, local regulations, and desired aesthetic appeal should be taken into account. The right choice of materials plays a crucial role in the overall success of the project, affecting structural integrity, durability, and maintenance requirements. To ensure long-lasting masonry work, it’s essential to choose high-quality materials that meet industry standards and are appropriate for the specific project. For example, in colder climates, it’s important to choose materials that can withstand freeze-thaw cycles. In earthquake-prone regions, using materials that provide better seismic resistance is essential.

In conclusion, understanding the properties and potential applications of various masonry materials is critical for the successful planning and execution of construction projects. The ability to choose suitable materials based on factors such as durability, performance, and aesthetic appeal can greatly contribute to the overall success and longevity of your masonry project.

Techniques and Best Practices in Masonry Construction

In this section, we delve into the various techniques and best practices associated with masonry construction. These methods can have a significant impact on the quality, durability, and efficiency of masonry projects. As a construction specification expert, I will provide you with valuable information on traditional bricklaying, dry stack stone masonry, veneer masonry, and the essential tools and equipment that ensure optimal results.

Traditional Bricklaying

Traditional bricklaying is a popular method of masonry construction that primarily relies on the use of bricks and mortar. This technique can suit various applications, from residential to commercial projects. Some advantages of traditional bricklaying include the following:

- High load-bearing capacity

- Excellent fire and weather resistance

- Customizable patterns and designs

However, it’s essential to note that traditional bricklaying can be time-consuming and labor-intensive, especially when compared to more modern methods like prefabricated panels.

Dry Stack Stone Masonry

Dry stack stone masonry does not use mortar, making it a more sustainable and environmentally-friendly technique. This method involves carefully stacking and interlocking stones to build walls and structures. Some of the benefits of dry stack stone masonry include:

- Improved drainage and reduced trapped moisture

- Ease of modification and repair

- Lower labor and material costs

The main drawback of dry stack stone masonry is the lower load-bearing capacity when compared to traditional bricklaying.

Veneer Masonry

Veneer masonry is a lightweight and cost-effective alternative to solid masonry construction. In this technique, a thin layer of bricks, stones, or manufactured materials is attached to a structural backing, such as concrete or steel. Advantages of veneer masonry include:

- Reduced material and labor costs

- Speedier construction process

- Versatility in design and aesthetics

However, veneer masonry has limitations in terms of structural capacity and may require additional reinforcement in some cases.

Masonry Tools and Equipment

Achieving quality construction results heavily relies on the appropriate use of masonry tools and equipment. Some essential tools for masonry professionals include trowels, levels, jointers, and brick/block splitters. Additionally, using scaffolding and mortar mixers can increase efficiency and safety on the job site.

Industry-Standard Guidelines and Quality Control

To ensure successful project outcomes, it is crucial to follow industry-standard guidelines and maintain quality control throughout the masonry construction process. The American Concrete Institute (ACI), ASTM International, and the Masonry Society (TMS) are reputable organizations that provide valuable guidance and resources for masonry professionals.

In conclusion, understanding the various techniques and best practices in masonry construction is vital for construction professionals. By implementing appropriate methods and adhering to industry standards, masonry projects can achieve optimal results in terms of quality, durability, and efficiency.

Masonry Reinforcement, Joints, and Connectors

In this section, we will delve into the essentials of masonry reinforcement, joints, and connectors. As a construction specification expert, I cannot emphasize enough the importance of these components in ensuring the structural stability, durability, and overall success of masonry projects.

Reinforcement in Masonry Construction

Reinforcement is essential for enhancing the structural performance of masonry construction. There are various options available for masonry reinforcement, including:

- Steel Reinforcement Bars (Rebars): Steel rebars are widely used to provide tensile strength and ductility to masonry structures. They are typically embedded within grouted cells in the masonry walls to enhance load-bearing capacity and resist lateral forces.

- Grouted Cells: Grouting is the process of filling the cells of concrete masonry units (CMU) with concrete-like material. This increases the wall’s structural performance and provides a solid matrix for embedding reinforcement bars.

- Fiber Reinforcement: The use of fiber reinforcement, such as glass, carbon, or polymer fibers, is becoming increasingly popular, contributing to the improved tensile strength, crack resistance, and durability of masonry construction.

Masonry Joints

Joints play a crucial role in masonry construction, as they help to distribute loads, accommodate movement, and prevent moisture penetration. The most common types of joints include:

- Mortar Joints: These joints are formed by laying bricks or blocks in a bed of mortar. Mortar joints contribute to the compressive strength, load distribution, and overall appearance of the masonry.

- Control Joints: Control joints are designed to manage the movement caused by shrinkage, temperature changes, and other factors. They help to minimize the risk of cracking in masonry walls.

- Expansion Joints: Expansion joints accommodate the expansion and contraction of masonry walls due to temperature fluctuations. These joints are usually placed at regular intervals and filled with flexible sealants to maintain an effective barrier against moisture penetration.

Connectors in Masonry Construction

Connectors, such as wall ties and anchors, play an essential role in maintaining the stability and integrity of masonry structures. They help to transfer loads, align masonry elements, and ensure the overall performance of the masonry construction.

- Wall Ties: Wall ties are used to connect masonry veneer to its backing material, such as a wood or steel frame. They provide lateral support and prevent the separation of the veneer from the backing structure.

- Anchors: Anchors are used to secure and stabilize the masonry structure to other building elements, such as floors, roofs, or adjacent walls. They help to resist lateral forces, maintain alignment, and distribute loads across the masonry.

By understanding the importance of masonry reinforcement, joints, and connectors, construction professionals can ensure the structural stability and durability of their masonry projects. In the next section, we will discuss the performance, maintenance, and sustainability aspects of masonry construction, and how these factors contribute to the overall success of the project. Stay tuned!

Masonry Performance, Maintenance, and Sustainability

In this section, we will delve into the performance criteria that impact the longevity and success of masonry structures, address regular maintenance requirements, and highlight the importance of incorporating sustainability into masonry projects. Our goal is to provide insights for construction professionals to optimize the performance, durability, and ecological impact of their masonry projects.

Structural, Thermal, and Water Performance

A key aspect of masonry performance is its structural capacity, which entails the ability of the structure to withstand loads and forces acting upon it. Properly designed and constructed masonry structures should have the required strength, stiffness, and stability to ensure long service life. The choice of materials, reinforcement, and construction techniques all play significant roles in achieving these structural goals.

Thermal performance is another crucial aspect, as masonry structures with good insulation can help in reducing energy consumption and maintain comfortable indoor temperatures. Insulated concrete block systems, autoclaved aerated concrete, and natural stone with appropriate design measures are examples of masonry materials that can contribute to enhanced thermal performance.

Water resistance is essential in masonry construction since moisture can lead to problems such as mold, mildew, and structural degradation. Proper design and detailing, including the installation of water repellents, vapor barriers, and flashing, are essential to prevent water intrusion and ensure lasting durability.

Fire Resistance

Masonry inherently boasts excellent fire-resistant properties, given that most of its constituent materials are non-combustible. Properly designed masonry structures can achieve high fire-resistance ratings, adding to the overall safety and resilience of the building. Combining masonry with other fire-resistant materials and incorporating fire barriers can further enhance fire performance.

Masonry Maintenance

Regular maintenance plays a crucial role in preserving the structural integrity and appearance of masonry structures. Brick and stone masonry requires a periodic inspection to identify and address any defects, such as cracks, spalling, or efflorescence. This helps in preventing further issues and prolonging the life of the structure.

Repointing mortar joints, replacing damaged bricks, and applying appropriate sealants and coatings are essential maintenance tasks that will keep masonry structures in good shape. It is vital to adhere to industry recommendations and best practices when performing maintenance tasks to avoid causing more harm than good.

Sustainability in Masonry

Masonry construction offers numerous opportunities to incorporate sustainable principles and practices. Using locally sourced and recycled materials can reduce the environmental impact of material extraction and transportation.

Many masonry materials, such as brick and concrete block, can be manufactured with a high percentage of recycled content, promoting a circular economy in construction. Designing energy-efficient masonry structures contributes to lower energy demand and greenhouse gas emissions.

Furthermore, masonry’s inherent durability, long lifespan, and potential for reuse or recycling at the end of its life make it a promising choice for sustainable construction projects. To make the most out of masonry’s sustainable potential, construction professionals must stay informed about the latest advances in materials and methods, and integrate sustainability considerations into their project planning and execution. By understanding the various aspects of masonry performance, incorporating regular maintenance, and prioritizing sustainability, construction professionals can ensure that their masonry projects provide lasting value, resilience, and ecological responsibility.

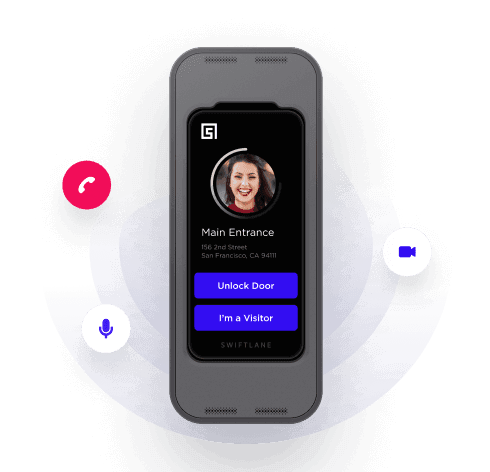

Upgrade Your Building Security

Get in touch with a Swiftlane specialist for more information on the best access control and video intercom solution for your building.